What is a cable gland

What is a cable gland

Defining Cable Glands

A device designed to permit the entry of a cable, flexible cable or insulated conductor into an enclosure, and which provides sealing and retention.

It also provides significant functions such as earthing, bonding, insulation, cable guarding, strain relief or a combination of these. They are mechanical fittings that form part of the electrical installation material.

A cable gland (also known as a cable connector or fitting) is a device designed to attach and secure the end of an electrical cable to the equipment.

A cable gland provides strain-relief and connects by a means suitable for the type and description of cable for which it is designed—including provision for making electrical connection to the armour or braid and lead or aluminium sheath of the cable, if any. Cable glands may also be used for sealing cables passing through bulkheads or gland plates.

Cable glands are mechanical cable entry devices. They are used throughout a number of industries in conjunction with cable and wiring used in electrical instrumentation and automation systems.

Cable glands may be used on all types of electrical power, control, instrumentation, data and telecommunications cables. They are used as a sealing and termination device to ensure that the characteristics of the enclosure which the cable enters can be maintained adequately.

Cable glands are made of various plastics, steel, brass or aluminum. Glands intended to resist dripping water or water pressure will include synthetic rubber or other types of elastomer seals.

Certain types of cable glands may also serve to prevent entry of flammable gas into equipment enclosures, for electrical equipment in hazardous areas.

Although cable glands are often called “connectors”, a technical distinction can be made in the terminology, which differentiates them from quick-disconnect, conducting electrical connectors.

For routing pre-terminated cables (cables with connectors), split cable glands can be used.

These cable glands consist of three parts (two gland halves and a split sealing grommet) which are screwed with a hexagonal locknut (like normal cable glands). Thus, pre-assembled cables can be routed without removing the plugs.

Alternatively, split cable entry systems can be used (normally consisting of a hard frame and several sealing grommets) to route a large number of pre-terminated cables through one wall cut-out.

There are at least three types of thread standard used:

Cable Gland Parts

Above is a typical CMP double seal Cable Gland showing the parts in an exploded view

Note : CMP is a Manufacturer of cable of glands

(1) Unique Independent Inner Sealing

The CMP inner sealing principal is quite different from other cable gland types and because the activation of the inner sealing ring is separated from the armour clamping components this means that the possibility of inadvertent over-tightening is eliminated.

Unlike traditional compression seals that have no means of direct control on their application, the CMP inner sealing technique is achieved using a displacement seal that is independently controlled by the user during installation.

The Compensating Displacement Seal System (1) has helped CMP to take its original displacement sealing ring concept to another level.

The unique Compensator has allowed the cable gland components to be fully tightened metal-to-metal and relieve the potential excess forces that could be transferred to the cable bedding, eliminating potential cable damage and coldflow.

(2) (3) Secure Armour Termination

CMP Products’ armour clamping method involves a unique termination solution that ensures a permanent crimping of the cable armour, creating a low impedance connection that does not suffer from self-loosening.

The patented AnyWayTM clamping ring aids an easy ‘Right First Time’ installation. Secure armour clamping like this also contributes to enhanced levels of EMC performance as well as reliable earth continuity.

(4) Outer Seal

The unique CMP Products Outer Seal Tightening Guide (OSTG) and Load Retention Sealing Ring (LRS) ensure an IP/NEMA rated seal is formed around the cable to the correct degree.

As similar solution is also provided for the sealing rings in our Cable Glands for unarmoured cables.

(5) Proven Internally Enclosed Deluge Seal

CMP Products integrated ‘O’ ring deluge seal (tested to DTS 01:91) prevents corrosion of the cable armour by ensuring that moisture cannot track around the Cable Gland threads and into the armour termination body.

As an internally enclosed deluge seal the ‘O’ ring is protected from mechanical damage and harmful UV rays.

What Is a Cable Gland?

A cable gland, also known as a compression fitting or cable entry, leads the cable into the housing in a sealed and strain-relieved manner. Plugs, terminal boxes or control cabinets, control panels, boom boxes, crane blocks or wiring boxes are used as enclosures. A cable gland ensures that the cable is securely sealed at the passage through a side wall or sheet metal plate into the terminal compartment. In addition, it ensures that the control cabinet is protected from external influences (e.g. dust or moisture). Depending on the area of application and environmental influences, additional properties such as EMC compatibility or ATEX approvals for EX-protected areas must be taken into account.

Cable glands don’t only seal or relieve the lines, they also prevent the cable from kinking thanks to special anti-kink sleeves. A cable gland therefore protects electrical equipment itself and also ensures that cables connected to a control cabinet continue to function properly.

The classic manufacturers of cable glands include:

Nowadays, metric threads according to DIN EN 60423 are mostly used. In addition to metric threads, PG cable glands (armored steel pipe thread) in accordance with DIN EN 62444 are used in some exceptional cases, mostly in older applications that are converted, repaired or retrofitted. For all cable glands there are corresponding expansions or reductions to be able to adapt the screw connection to any existing thread. If the cable gland is installed in a through hole instead of a thread, it must be locked with a corresponding counter nut.

Areas of application

Cable glands can be found in a wide variety of areas, including the following:

Due to their diverse areas of application, they have to meet a wide range of requirements in terms of protection class, continuous use temperature, explosion protection, impact resistance or EMC (electromagnetic compatibility).

In chemical engineering and in the food industry, for example, cable glands made of stainless steel (INOX 1.4305) are used. The use of stainless steel is mandatory for hygienic and health reasons or due to the use of sometimes aggressive cleaning agents and chemicals in both industries. Stainless steel is a resistant material and withstands external influences particularly well. Depending on the area of application, other factors should be taken into account in addition to the suitable material.

How do I choose the right cable gland?

The following 3 factors must be considered when making a selection:

1. Thread size

In order to combine the different cable diameters with the thread size intended for the cable gland, the glands are divided into different clamping areas. The metric dimension (M) forms the nominal size for cable glands in combination with the following digits for the thread size.

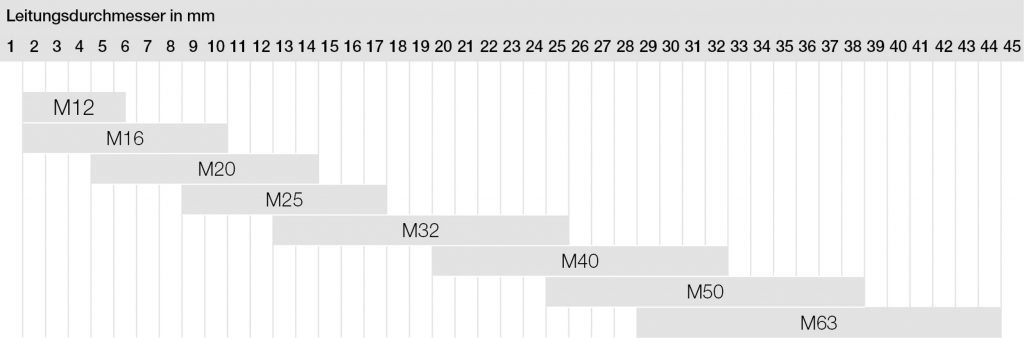

The following table will help you choose the right cable gland:

Division of the screw connections into the various clamping areas (Translation: Line diameter in mm)

2. External influences

In certain areas of application, the screw connections are exposed to moisture or water. A degree of protection of the plug is necessary here to protect against the ingress of moisture or water into the housing. Depending on the area of application, protection against contact and foreign bodies should also be taken into account.

3. Material

Depending on the type of external influences to which the cable gland is exposed, it is important to choose a material for the gland that is suitable for the area of application.

As already described, cable glands made of stainless steel are used, for example, in the food and chemical industries.

Brass cable glands are usually used in «hazardous areas», such as those found in the oil and gas industry.

Cable glands with the material property «brass nickel-plated» are often found in very harsh industrial applications or in an EMC-compatible variant with a special shield concept.

Plastic cable glands made of polyvinyl chloride (PVC), polyvinylidene fluoride (PVDF) or polyamide (PA) are also used in industry depending on the application and environmental conditions.

Does igus® offer cable glands?

Can’t find what you’re looking for? We would be happy to assist you in choosing the right cable gland for your application. Contact an igus® expert here.

Most Recent Articles

What can curved rails offer that standard rails can’t?

Read this blog to learn more about drylin® curved rails and some of the advantages they offer over more standard linear rails.

How does 3D printing reduce waste?

Learn about the ways in which 3D printing can reduce waste and improve sustainability over subtractive manufacturing methods such as CNC machining.

Are igus® products compatible with ISO cleanroom standards?

Read this blog to learn how igus® is developing cleanroom compatible products, certified by Fraunhofer IPA’s ISO cleanroom standards.

Can Robotics Save the Food Industry?

Read this blog to learn about how automation can be applied to the food industry to increase production, adapt to global events such as Covid, and improve worker safety.

Car Actuators – Go lighter, quieter, and corrosion-resistant

Read this blog to find out how igus® self-lubricating lead screws, lead screw nuts and linear actuators can be applied in the automotive industry

Returning to the office? Try these strategies to help manage the transition successfully

Stressed about returning to the office after adjusting to working from home? Read this blog for strategies on how to make the transition as smooth as possible.

Going Carbon Neutral – Corporate CO2 Footprint

Read this blog to learn how igus® is adapting its policies to reduce carbon emissions, aiming to become completely climate-neutral by 2025

5 Industrial IoT Solutions for Manufacturing

Read this blog to learn about how industrial IoT can solve some of the most common issues in the manufacturing industry.

What are the best cables for robotic applications?

Read this blog to learn what makes a cable suitable for robotic applications, and why pairing those cables with a quality cable carrier is essential.

Are lubricants really needed for format adjustments in packaging machines?

This blog covers the advantages of using self-lubricating plastic lead screw nuts over traditional metal lead screw nuts

New Electric Unit Takes ATV Market for a Ride

Learn about the newest design arriving in the ATV market, and igus’ part in creating this innovative vehicle.

The Future of Electric Vehicles in the US

Learn about the future of electric cars in the United States and the role igus® products play in electric vehicles.

Smart factory: intelligent plant monitoring with the FANUC FIELD system

For machine data evaluation in the smart factory, FANUC offers the «FIELD system» industrial IoT platform. igus® is also involved with its i.Cee app for predictive maintenance.

How are chainflex® cables compliant with NFPA 79?

In this blog post, we’ll explain 7 ways that chainflex® cables meet the requirements of the relevant sections in NFPA 79 that address cables used in flexing applications.

Significantly reduce maintenance costs with smart condition monitoring systems

A BREAK-EVEN ANALYSIS OF THE USE OF IGUS I.SENSE IN MAINTENANCE

Sliding vs Rolling: Benefits of Plastic Linear Bearings

Learn about the advantages of implementing plastic linear plain bearings into applications as well as how to correctly do so. Optionally, watch the webinar, complete with informational slides.

What is a cartesian robot and how is it used in automation?

Learn about cartesian robot applications, advantages to other robot systems, types of motor controllers and drivers and a new configurator tool

Science Friction Episode 5: Alfred from Dexai Robotics

In this episode, Hosts Adam and Avory speak with Justin Rooney from Dexai Robotics about their flexible robotic arm (and sous chef), Alfred.

Don’t Sweat It: Self-lubricating Compound Polymer Bearings for Fitness Equipment Are Maintenance-free

In this blog post, we will explore the main advantages of self-lubricating compound polymer bearings most relevant to the fitness equipment industry.

Science Friction Episode 4: The M1 Caliber from REEKON Tools

In this episode, hosts Adam and Avory speak with Alex LeGendre, a former project manager at REEKON Tools, about the company’s measuring device called the M1 Caliber.

Cable Glands: What They Are, Their Uses, And How They Work

If you are a student, tradesman, or engineer, then you may have heard the term “cable gland” before, but do not know what they are or what it is used for. In this article, we will be discussing what cable glands are and their many uses. We will also take a look at how they work and some of the different types that are available on the market. So, whether you’re new to the world of cable glands or just want to learn more about them, read on!

Cable glands are used in a number of electrical systems and applications but what are they actually used for? Cable glands are typically used on cable sizing from 1mm up until around 80mm cable diameters.

Cable glands can also be known as cable grips, cord grips, glands, cable connectors, cable fittings, or cable strain reliefs.

What is a cable gland?

A cable gland is a type of device that is used to terminate and secure the end of a cable. The cable gland is fitted over the end of the cable and then tightened, which compresses the gland around the cable. This provides a watertight and secure connection. Cable glands are used in many different applications, such as in computer equipment, electrical panel boards, and cable television systems. Cable glands are defined as a mechanical entry points for an electrical cable in an electrical system or panel. They are used in conjunction with electrical cable or wiring in a number of different systems.

A cable gland provides a secure entry for an electrical cable into enclosures such as electrical or instrumentation panels. They provide sealing, security, and protection to electrical systems, cables, and enclosures.

Cable glands come in many different sizes and styles, depending on the application. Some common types of cable glands include a compression gland, clamping gland, locking gland, strain relief gland, and weatherproof gland. Compression glands are used to terminate non-armored cables. Clamping glands are used to terminate armored cables. Locking glands provide a locking mechanism to prevent the cable from being disconnected. Strain relief glands are used to relieve stress on the cable. Weatherproof glands provide a seal against moisture and dust.

Cable glands must be installed correctly in order to work properly. Incorrect installation can result in damage to the equipment or failure of the connection. When installing a cable gland, it is important to follow the manufacturer’s instructions.

What does a cable gland look like?

The image below shows the typical construction of a cable gland. It also shows all of the individual components that make up a cable gland and where they are located.

From left to right.

Nut – the nut on the left-hand side locks the gland inside the panel or cabinet. This securely fixes the gland in place.

Body – this part is where the cable slides through and is gripped by the mechanism on the right-hand side. This closes up as the nut is tightened.

Seal – the seal is located at the end of the body where the cable enters. The seal provides extra protection from water ingress and dust/dirt.

Nut – the final nut secures the cable in place. Tightening up this nut means that you will not be able to move the cable and it will be mechanically locked.

What is the purpose of a cable gland?

The cable gland’s main purpose is to protect an electrical system or component at the entry point for the cable. They protect from dust, water ingress, and any dirt getting into the panel or enclosure where the cable enters. They also grip the cable which protects it from being pulled out of terminations if the cable is caught or pulled.

They do this by:

Where are cable glands used?

Cable glands are used on electrical and instrumentation panels that require cable entry. They can be found on nearly every electrical panel that you may come across. Electrical panels for machinery can be located in wet factory environments or exposed to every weather condition outside. Cable glands protect from water ingress and any dirt or dust entering a panel via the cable entry points.

Cable glands can also be located on local isolator boxes, electrical motor terminal boxes, and much more electrical equipment.

What are cable glands made from?

Cable glands can be manufactured from a number of different materials, some of the most common types are ones manufactured from either metals or plastics. The choice of material depends on what cable type you are using, the environment, and whether or not the gland needs to be corrosion resistant or not.

Stainless steel cable glands tend to be more expensive but they are generally stronger and can be tightened to a high level to protect against any kind of unwanted ingress.

Plastic cable glands can be used in applications where harsh chemicals or a lot of water is being used. This type of cable gland is corrosion resistant and still provides a high level of sealing.

Brass cable glands are generally used in instrumentation, machinery, and the medical industry. Brass cable glands provide excellent corrosion-resistant properties.

How To Select The Correct Cable Gland

There are several factors to consider when selecting the correct cable gland for your application, such as the environment in which it will be used, the type of cable being used, and the required level of protection.

Cable glands are typically made from metals such as brass, stainless steel, or aluminum, and are available in a variety of sizes to accommodate different cable diameters.

To ensure a proper fit, it is important to measure the diameter of the cable before selecting a gland. The diameter can be measured with a ruler or caliper and should be taken at the widest point of the cable insulation.

Once you have selected the correct size gland, the next step is to determine the appropriate thread type. The most common types of threads used on cable glands are NPT (National Pipe Thread) and BSP (British Standard Pipe).

When installing a cable gland, it is important to follow the manufacturer’s instructions carefully. In most cases, the gland will need to be tightened by hand until it is snug against the cable insulation. Once the gland is tight, you may need to use a wrench to finish tightening it.

Cable glands provide an important function in ensuring the safety of electrical systems by providing a secure connection between cables and enclosures. By taking the time to select the correct gland for your application, you can help to ensure the safety and longevity of your system.

Hi, I’m Liam, I started Engineer Fix with the vision of providing students, engineers and people that may be curious with an online resource that can make engineering easy.

I have worked in various roles within engineering performing countless hours of mechanical and electrical work/projects. I also completed 6 years of training which included an advanced apprenticeship and an HNC in electrical engineering.

What is a Cable Gland? 6 Types of Cable Glands with Size Chart

What is a Cable Gland? 6 Types of Cable Glands with Size Chart

Why are we using cable glands on cables? How many types of cable glands are we use in the electrical industrial sites? What are the sizes of cable glands used in the electrical construction? You will get an answers for theses questions from this article. So, don’t skip and read completely.

Table of Contents

What is a Cable Gland?

Cable gland is designed to permit the entry of cable in to electrical equipment or component which provide earthing, grounding, bonding, insulation, sealing, retention and strain relief. It provides mechanical supports for cables.

Glanding and termination are a major work to the electricians while constructing a site. There are various types of glands are used in the oil and gas areas. There are two types on industrial cable gland. One is single compression glands. Another is double compression glands.

Electricians must use a proof type of gland in an abnormal situation, such as flame-proof, explosive proof, fire proof.

In small type of industries, we should have to use single compression glands. We commonly use double compression glands in the plants and large size construction areas.

Part names of single compression glands are check nut, gland body, washer, ring and compression nut.

Types of Cable Glands : Single and Double Compression Cable Gland

There are four types of glands are used in the electrical construction. Single compression gland should be only used in the small type industries. Double compression glands should be only used in the plant.

Flexible hose glands are used in the heat areas. PVC glands are used for the control cables. Purpose of use of this gland for mechanical support and earthing.

Parts name – Body, washer, nut, ring and cone.

The four type of glands, classified by construction method. These are, 1. Single compression 2. Double compression 3. Flexible hose 4. PVC.

Single Compression Cable Gland

This type of glands are commonly used in buildings and small industries. We should use single compression gland for the flat armored cables. There are three types of single compression glands available in electrical industries. They are,

Double Compression Cable Gland

In power plant and oil and gas plants, we use double compression. We should use double compression gland for the round armored cables. Three types of double compression glands are used in electrical industries. They are,

Flexible Hose and PVC Gland

PVC glands are commonly used for the control cables in the instrumentation field. Flexible hose glands are used in the heat areas.

Correct Selection of Cable Glands

Gland should be selected on following factors,

6 Types of Cable Gland

There are 6 types of glands are used in the construction sites. They are,

Brass Indoor Type Gland

The gland is good handling in use with different types of cable whether plastic, rubber, metal or any other. This type of glands are used in dry indoor areas and used with all type of single wire armored cables, plastic or rubber sheathed cables. Brass indoor gland suitable for single wire armored, plastic or rubber sheathed cable. We should have to use shroud for ingress protection. We use this type for SWA armored cables.

Brass Outdoor Type Gland

This type is made by high quality material for use in outdoor purpose with different types of cables sheathed or unsheathed. Brass indoor and outdoor glands commonly used with single wire armored(SWA). Plastic or rubber or metal sheathed cable. Terminates and secure cable armoring and outer seal grips sheath of cable thus ensuring mechanical support and earthing. Use shroud for additional protection.

Application : Outdoor or indoor, for use with all type of single wire armored cables, plastic or rubber sheathed cable. Popularly used for SWA, plastic of rubber sheathed cables. Used in dry indoor conditions.

Additional materials: earth tag, PVC shroud, rubber, washer, brass lock nut. Cable type: wire braid armor.

Brass Straitening Unarmored Gland

This type of glands are used for different type of unarmored or rubber sheathed cables. Brass indoor and outdoor gland suitable for all types of unarmored cables, plastic or rubber sheathed cables.

Applications: used on unarmored and plastic insulated cables. Indoor & Outdoor wherever it is required to provide sealing on cable outer sheath.

Additional materials: earth tag, pvc shroud, rubber, washer, brass lock nut. Cable Type: wire braid armour.

Brass Weatherproof Gland

This type electrical gland is used precisely with armored different types of SWA cables (electrical full form is Single Wire Armour) whether plastic or rubber sheathed ones. This type gland is known for its uninterrupted services once the gland is fixed to the cables.

This is suitable for single wire armour or rubber sheathed cables. Outer seal grips bedding layer of cable for use in most climatic situations. Manufactured in various proof type like weatherproof and waterproof. It has a separate armour lock rings.

Application: In Outdoor or indoor, for use with single armored, all type of SWA cable, plastic or rubber sheathed cable. It is also available in weatherproof and waterproof. Inner and outer sheath.

Cable type: Steel Wire Armour (SWA).

PG Threaded Gland

The type is a custom made threaded gland to meet the needs from the industries.

Industrial Gland

Industrial brass glands suitable for wire braid armored, plastic or rubber sheathed cable. Terminates and secure cable armoring and outer seal grips sheath of cable thus ensuring mechanical strength and earth continuity. For additional protection use PVC shroud.

Cable type: Wire Braid Armour.

Brass gland suitable for steel tape armored, plastic or rubber sheathed cables.

Types of Cable Glands

Cable glands are a common feature of panel assemblies and electric infrastructure used to mount wires and protect cables. These devices vary widely, with designs for a variety of applications and environmental conditions. Here, we’ll answer some of the most common questions about cable glands. Read on to discover answers to what are cable glands used for, what are the different types of cable glands and how do you choose one for an application?

Table of Contents

What Are Cable Glands?

Cable glands are defined as mechanical cable entry modules, which means they are used to attach electrical cables to equipment securely. Unlike household plugins and other conducting electrical connections, cable glands are not made for quick disconnections. Instead, they provide a secure and long-lasting connection to a device. Cable glands go by many names — you may see them referred to as a:

No matter the name, cable glands serve almost any industry that uses electrical equipment in some capacity. Cord grips are used for cables and wiring in a range of electrical, instrumentation, control and automation systems, offering uses for power, data and telecommunications wires.

What Are Cable Glands Used For?

The first question to answer is why do we use cable glands? In short, cable fittings are considered critical safety devices for electrical installations. Their primary purpose is to act as sealing and terminating devices between a cable and its connected electrical equipment. In this role, cord grips serve a few core purposes:

Different Types of Cable Glands

With so many applications for cable fittings, there is a huge range of cord grips available. So how many types of cable glands are there? There are as many varieties as there are applications. Most cable fittings are characterized by factors such as materials, armor compatibility and application-specific needs. Below are some of the most common features for cable fittings organized by category:

1. Material Features

The most basic differentiation between cable fitting designs is their materials. Some of the most common materials used for cable glands include:

2. Armor Compatibility Features

Another basic difference between cable strain reliefs is whether they’re suitable for armored or unarmored cables. Industrial cable glands are available for both varieties. Know what type of cable your operation uses to determine the right cord grip for the application, whether you have:

3. Application-Specific Features

Another way to define cord grip varieties is by the protection they provide or their ability to suit needs in specific environments. Application-specific cable gland varieties include:

Cable Gland Designations

You will often see cable glands given specific designations according to BS 6121. This British Standard was originally a standardization method for cable strain reliefs in the industrial sector and specified requirements for different designs. Although this is no longer the most current standard in the EU, it still serves as a valuable designation among manufacturers to communicate types of glands and their key features. Some of the most common types and designations include:

1. Type A Cable Glands

Type A glands may also be referred to as “stuffing glands” and are commonly used on unarmored plastic or rubber-sheathed cables. There are four A-type designations:

A-type glands are often used in indoor and outdoor applications where armored cables are unnecessary.

2. Type B Cable Glands

Type B cable glands are designed for use on single-wire armored cables made with plastic or rubber sheaths. The glands themselves are made of brass and are designed for securing the cable’s armor and providing an electrical path between the armor and the gland. These cord grip designs are made for use in indoor applications where moisture exposure is low.

3. Type C Cable Glands

Type C cable glands are designed for use on plastic or rubber sheathed cables with armor or braiding. Type C cables are made of brass or stainless steel and serve a similar purpose as the type B cable gland.

The primary difference between the two designations is that the type C cord grip features an IP68-designated seal between the outer sheath and the gland. This seal provides an extra level of protection against moisture and environmental exposure, making this connector design suitable for outdoor applications with a greater need for weatherproofing and waterproofing.

4. Type D Cable Glands

Like B-type cables, type D cables are designed for use on armored or wire braided lines with plastic or rubber outer sheaths. The key difference between this cable gland variation and the type B cable gland is that it features an IP68-designated seal between the inner sheath and the threaded fixing part.

There are two variations of the type D cable gland:

5. Type E Cable Glands

Type E cable glands are used on cables with armor or braiding and plastic or rubber outer sheaths. The type E cord grip is often made of brass or stainless steel. It’s similar to the C-type cable connector design, with an armor locking ring and inner and outer seals rated to IP68. The outer seal grips the cable sheath, while the inner seal grips the cable’s bedding layer.

There are two variations of the type E cable gland:

Type E cable glands are highly suitable for applications with exposure to the elements as the seal features of E variation offer excellent waterproofing and weatherproofing.

6. BS 6121 Suffixes

In addition to the variations above, cord grips with B, C, D, and E designations will also often feature a suffix along with the classification. This suffix indicates the specific armoring the gland is designed for. These suffixes are defined as follows:

In practice, the cable gland will be designated with their cable type first and their protection suitability immediately after. For example, a type C cord grip designed for a single wire armored cable will have a designation of “CW.” If a gland design may be used for more than one armoring variation, all the relevant suffixes will be added after the cable gland type. For example, a type B cable connector designed for both single and pliable wire armored cables will have a designation of “BWT.”

How to Choose a Cable Gland

With so many different cable connector features and designs to sift through, it can be challenging to determine which type of cable gland to use for a specific application and what features to look for. The key to making this choice is to identify the application’s needs first and then eliminate cable fitting options using this information. Some key questions to ask when selecting a cord grip include:

Once you have narrowed down your cable gland options to suit your application’s needs, you can then make a final decision based on cost.

Shop Cable Glands From AerosUSA, Inc.

Cable glands are a small yet essential piece of equipment in nearly every industry. Whether you’re working in the aerospace, marine, power, telecom or industrial sectors, cable glands are a key safety feature. The importance of cable fittings can’t be understated, so it’s essential to find quality designs that fit perfectly into your application and environment. AerosUSA can help.

AerosUSA is a leading supplier of wire and cable protection systems. Our products, manufactured by Flexa GmbH, include everything from cable covers and shielding systems to high-quality cable glands. Our experience spans a range of industries, and we carry a selection of products that is just as diverse. On top of it all, we offer quick responses, competitive pricing and fast turnaround times.

Contact AerosUSA today to learn more about cable glands and our selection.