What is carbon nitride

What is carbon nitride

Carbon Nitride

Graphite carbon nitride (g-C3N4) is a photocatalyst that is attracting more and more attention.

Related terms:

Download as PDF

About this page

Photocatalytic performance of hexagonal boron carbon nitride nanomaterials

5.4 Photocatalytic oxidation of alcohol

Current development of graphitic carbon nitride photocatalysts as one of the organic semiconducting photocatalytic materials

4 Nanostructure design

Reproduced with permission from P. Yang, H. Ou, Y. Fang, X. Wang, A facile steam reforming strategy to delaminate layered carbon nitride semiconductors for photoredox catalysis, Angew. Chem. Int. 56 (2017) 3992–3996 (Copyright 2017, Wiley-VCH).

Reproduced with permission from H. Ou, L. Lin, Y. Zheng, P. Yang, Y. Fang, X. Wang, Tri-s-triazine-Based crystalline carbon nitride nanosheets for an improved hydrogen evolution, Adv. Mater. 29 (2017) 1700008 (Copyright 2017, Wiley-VCH).

Sustaining the inherent structure of 2D crystals, the ultrathin tri-s-triazine–based crystalline carbon nitride nanosheets provide a broad range of applications in the fields of bioimaging, energy storage, and conversion, as well as host nanosheets to make couples with second semiconductors or metals to create variety of functional 2D nanocomposites.

The photocatalytic activity of both inorganic and organic semiconductor materials strongly depends on their bulk crystallinity, morphologies, and surface structures. Carbon nitride (CN) aerogel nanomaterials exhibit specific physicochemical properties, being superior to those of the conventional nanoparticles (NPs). Therefore, CN aerogel nanomaterials have attracted increasing research interest in the fields of energy storage and conversion. However, there are big impediments which should be overcome to construct CN aerogel structure because the original materials have several weak points such as very limited active groups at the edges on surfaces, large lateral spaces, rather low thermal stability, and insolubility in most conventional solvents.

Reproduced with permission from H. Ou, P. Yang, L. Lin, M. Anpo, X. Wang, Carbon nitride aerogels for the photoredox conversion of water, Angew. Chem. Int. 56 (2017) 10905–10910 (Copyright 2017, Wiley-VCH).

Surface and Hidden Surface-controlled Carbon Alloys

(b) Doping of foreign atoms or clusters

Carbon and boron nitride share common allotropes; there are the hexagonal graphitic form and the cubic diamond one. However, there is a distinct difference between carbon and boron nitride in the nature of the interatomic bonding. Boron nitride has a polar character due to the boron–nitrogen bond (–N − B + –), while graphite and diamond have no polar character in the carbon–carbon bonding. Borek et al. [ 30 ] prepared a microporous boron nitride. Doping of foreign atoms having different valence and electron negativity in the graphitic frame can vary partially the bonding character, as shown by boron nitride. The doping of foreign atoms can be selectively done on the hidden and external surfaces in order to promote specific functions.

Carbon-supported semiconductor nanoparticles as effective photocatalysts for water and wastewater treatment

2.9 Graphitic carbon nitride

Graphitic carbon nitride (GCN), low-cost metal-free polymeric semiconductor with high thermal and chemical stability has emerged as a promising support for photocatalysts for the degradation of organic compounds ( Ran et al., 2015 ; Zhang et al., 2018 ). These materials are synthesized by treating high nitrogen-rich organic precursors at higher temperatures to form a unique structure with good textual and morphological property ( Gong et al., 2015 ). GCN itself can be used as visible light catalyst, but the rapid recombination rate of electron-hole pairs and low quantum yield limits its potential application for pollutant degradation ( Zhu et al., 2014 ). Using GCN as a substrate to support photocatalyst for the degradation of organic compounds has a number of inherent advantages, including extending the light absorption into the visible region and minimizing the recombination of photogenerated electron-hole pairs in the electron transfer process and good visible light harvesting capacity ( Liu et al., 2015b ). Carbon-doped ZnO supported on GCN composites was synthesized through simple one-step calcination of an evaporation-dried mixture of dicyandiamide and zinc nitrate for the photocatalytic degradation of methylene blue ( Zhu et al., 2014 ). An enhanced photocatalytic activity of the composite was achieved due to the well-established heterojunction between GCN and ZnO, which initiated effective separation of the photoinduced electrons and holes. In another study, carbon-doped TiO2 supported on mesoporous GCN was prepared by a facile heating method for the visible light photocatalytic degradation of methylene blue ( Wu et al., 2016 ). The higher stability of the composite material together with enhanced visible light absorption and adsorption of dye on the photocatalyst resulted in four times higher degradation than that of carbon-doped TiO2. The heterojunction structures formed by the composites can facilitate the photocatalytic activity by retarding the recombination rate, enabling a larger amount of reactive sites with high surface-to-volume ratio and convenient mass transfer ( Chang et al., 2014 ; Wei et al., 2017 ).

Nanostructured photocatalysts: Introduction to photocatalytic mechanism and nanomaterials for energy and environmental applications

1.3.2 Two-dimensional g-C3N4 photocatalysts

Carbon nitride (g-C 3N4)-based photocatalysts have been viewed as a holy grail in the photocatalytic field since the first investigation reported by Wang et al. in 2009 ( Liao et al., 2019 ; Wang et al., 2009 ). The two-dimensional (2D) polymeric carbon nitride is a layered structure in which a monolayer is constructed by tri-s-triazine units connected by nitrogen atoms. The interlayer distance (d) was found to be 3.19 Å while the lattice distance (a) was 7.14 Å, as depicted in Fig. 1.9 ( Zhu et al., 2018 ). The CB and VB were found to be adequate for various essential applications such as hydrogen production, degradation of pollutants, and CO2 reduction ( Wen et al., 2017 ). Therefore g-C3N4-based materials are a potential candidate for solar-driven energy and environmental applications. However, limited solar absorption, low conductivity, and rapid charge carrier recombination are challenges lowering the photocatalytic activity of g-C3N4. Numerous attempts to improve the photocatalytic activities of g-C3N4-derived photocatalysts have been undertaken in the past decade ( Fu et al., 2018 ; Liao et al., 2019 ; Wen et al., 2017 ). Three primary approaches, namely morphology tailoring, structural engineering, and composites, have shown immense promise in addressing the current challenges of this class of materials.

Reprinted from Zhu, B.; Zhang, L.; Cheng, B.; Yu, J. First-Principle Calculation Study of Tri-S-Triazine-Based g-C3N4: A Review. Appl. Catal. B 2018, 224, 983–999.

Tong et al. (2017) prepared a multishell g-C3N4 nanostructure using silica spheres as the hard template. The formation of mesopores in a multishell structure is an ideal platform to enhance light absorption by light scattering and charge transfer from the bulk to the surface, leading to promote the production of hydrogen and the decomposition of the organic substances. In another approach, structural modifications of g-C3N4, through molecular tailoring-mediated donor-acceptor, has been gaining in popularity as a crucial method to improve photocatalytic performance. In a recent report, Zhang et al. (2018) used ionothermal synthesis to prepare a novel structure of g-C3N4 containing an internal triazine-heptazine heterostructure. The obtained triazine-heptazine configuration significantly promotes the charge separation leading to the remarkable promotion of produced hydrogen. Indeed, the produced hydrogen over the optimized sample (CN-NaK) was found to be

28 times higher than that of the conventional g-C3N4 (CN).

Recently, metal single-atom-incorporated g-C3N4 photocatalysts have received increasing attention because of the unique features of metal single atom, which assists in facilitating charge separation and surface chemical reactions. In such an investigation, Zhou et al. prepared Pt single-atom (PtSA)-modified g-C3N4 containing nitrogen vacancies ( Fig. 1.10 A and B ). It should be noted that the nitrogen vacancies have a crucial role in stabilizing the formation of PtSA through the strong chemical bonds between PtSA and the two-coordinated C (C2C) sites. The calculated adsorption energies reveal that PtSA favors localization at the C2C (nitrogen vacancies) because of its lower adsorption energy when compared with N2C sites. Such modifications prolong the lifetime of charge carriers, resulting in considerable facilitation of photocatalytic activity ( Fig. 1.10 C and D) ( Zhou et al., 2019 ).

Reprinted from Zhou, P.; Lv, F.; Li, N.; Zhang, Y.; Mu, Z.; Tang, Y.; Lai, J.; Chao, Y.; Luo, M.; Lin, F.; Zhou, J.; Su, D.; Guo, S. Strengthening Reactive Metal-Support Interaction to Stabilize High-Density Pt Single Atoms on Electron-Deficient g-C3N4 for Boosting Photocatalytic H2 Production. Nano Energy 2019, 56, 127–137.

Surface Science of Photocatalysis

15.5 Summary and outlook

Photocatalysts based on polymeric carbon nitride are promising functional materials for the potential solution to the increasing energy demand and environmental pollution. In this chapter, CN-based photocatalysts for H 2 production and CO2 reduction are comprehensively introduced in accordance with the strategies for increasing charge generation, boosting charge separation, and promoting the surface catalytic process. Particularly, hollow structure creation, elemental doping, and molecular structure modification could effectively enhance the light-capturing ability or extend the light absorption ability of CNs, thus absorbing abundant photons to generate more photoexcited charge carriers. Moreover, reducing the thickness of CNs and improving the crystallinity of CNs could promote the bulk-to-surface charge transport, while creating heterostructure of metal/CNs, graphene/CN, semiconductor Type II heterojunction, and direct Z-scheme heterojunction could boost the interfacial charge transfer of CNs. At last, creation of porous structure and surface defects, construction of hybrid materials of MOF/CNs, LDH/CNs, and facet tuning of metal cocatalyst could allow efficient mass transfer and molecule adsorption, which subsequently result in the effective activation of reactant molecules toward the effective utilization of the as-separated charge carriers.

Despite the great accomplishments demonstrating the extraordinary potential of CN-based photocatalysts in the field of solar-to-fuel conversion, significant challenges still remain in the current stage. First, from the material aspect, the second generation of CNs, i.e., crystalline CNs, seems to be promising in transferring photoinduced charge carriers. However, the reduction of defects may also weaken the adsorption ability toward reactant molecules. Hence, it is desirable to develop novel kinds of CNs to strike a balance between high crystallinity and useful defects, in order to simultaneously achieve improved charge transfer and molecular adsorption. Second, from the aspect of designing photocatalytic system, currently it is difficult to compare the performance of different photocatalysts due to the lack of unity of experimental conditions. The light source, the reaction medium, and the cocatalyst could be quite different in various studies. Therefore, a standard system which can be developed for the evaluation of photocatalytic performance could be beneficial for guiding the design of highly efficient CN-based photocatalysts. Third, current studies mostly focus on the photocatalytic H2 production in the presence of sacrificial agents. However, for the aim of real application, the photocatalytic H2 production based on overall water splitting is in fact much closer to the concept of “clean and renewable energy.” It is still challenging to obtain an efficient CN-based photocatalytic system for overall water splitting. In addition, both the activity and selectivity of photocatalytic CO2 reduction into hydrocarbon fuels are unsatisfactory up to now. It is necessary to develop novel CN-based materials and systems for the enhancement of such properties. Finally, to get an in-depth understanding at the atomic level, precise in situ observations based on advanced spectroscopic techniques and fundamental analysis based on professional theoretical simulation are very important to avoid detours in the research of CN-based photocatalysts for solar-to-fuel conversion.

Semiconductor @ sensitizer composites for enhanced photoinduced processes

2.2.3 g-C3N4

Graphitic carbon nitride (g-C 3N4), with a moderate band gap (

Possible applications of modified g-C3N4 photosystems are mainly focused on hydrogen evolution by water splitting, CO2 reduction, and pollutant degradation at ambient temperature. Another interesting use anticipated for metal-decorated g-C3N4 is hydrogen storage.

Hardmetals

1.06.3 Titanium Carbonitride

Titanium carbonitride, TiCN, is a cermet material with a wide composition range dependent on the ratio of C:N, usually expressed as TiC1−xNx. TiCN has several properties that make it of interest to the cutting tool industries. These properties include high hardness, high wear resistance, and chemical inertness. Typical properties of TiCN are listed in Table 10 ( Clark & Roebuck, 1992 ; Jha & Yoon, 1999 ).

| Property | TiCN |

|---|---|

| Molecular weight | 59.9-61.9 |

| Crystal structure | FCC (B1) |

| Density (g cm −3 ) | 6.0-6.8 |

| Melting point (°C) | 2950 |

| Microhardness HV30 | 1400-1750 |

| Transverse rupture strength (N mm −2 ) | 1400-1900 |

| Coefficient of thermal expansion (K −1 ) | 9.0 × 10 −6 |

| Thermal conductivity (W (m·K) −1 ) | 10 |

Hard TiCN particles are combined with a ductile binder phase to yield a cutting tool for applications beyond the capabilities of standard WC-Co grades. Applications using TiCN powder require very fine particle sizes and narrow particle size distributions. Various processing strategies are currently used to produce TiCN powder, with powder currently available in the market in the size range of 0.5-2.0 μm. Among the more commercial methods are plasma reaction, carbothermal reduction of TiO2, solid-state diffusion of carbon and nitrogen into Ti metal of carbide and nitride blends, self-propagating high-temperature synthesis, and titanium halide reactions involving TiCl4 ( Davidson, Shirts, & Harbuck, 1989 ; Leparoux, Kihn, Paris, & Schreuders, 2008 ).

Plasma synthesis of TiCN powders utilizes Radio Frequency inductively coupled plasma to control the stoichiometry and size of the powder. Precursors such as Ti metal or TiH are injected into the plasma, where they are evaporated in an RF plasma. The vaporized species are then reacted with a hydrocarbon source to form TiCN ( Davidson et al., 1989 ). Work by Grabis and Zalite (2005) demonstrated the ability to produce TiCN nanoparticles with an average grain size below 30 nm over a wide range in composition.

The carbothermal reduction of TiO2 accompanied by the simultaneous carbonitridation is considered to be the high-volume, low-cost synthesis process in an industry. The oxide feedstock is blended with carbon and reduced at elevated temperatures of 1300-1700 °C. The reduction of TiO2 liberates CO, with further reactions producing a locally equilibrated amount of CO2. The nitrogen flow will serve as a sweep gas for the CO/CO2 species and will also provide the reactant for the nitridation process ( Berger, Gruner, Langholf, & Stolle, 1999 ; Monteverde, Medri, & Bellosi, 2001 ). The reaction sequence is as follows.

Jha and Yoon (1999) have studied the carbothermal reaction in which the atmosphere ranged from pure N2 to blends of N2 + H2 + CO or NH3 + H2 + Ar. The time required for complete conversion is dependent on the reaction temperature. Alteration of the initial TiO2:C ratio or the ratio of the gases will also affect the degree of completion and mixture of phases formed in addition to TiCN, primarily Ti3O5 and C.

The high temperature diffusion process of preparing submicron TiCN can proceed with either TiN or TiC as feedstock ( Monteverde et al., 2001 ; Pastor, 1987 ). Three reaction sequences are available depending on the feedstock. When TiN is one of the starting materials, it is blended with TiC powder and then mixed by ball milling. The powder blend is then diffusion-treated under flowing nitrogen to yield TiCN, with the ratio of C:N determined by the ratio of the initial powders. Or, the TiN can be blended with carbon between 1300 and 1700 °C. If TiN is not used as one of the starting materials, then Ti metal and TiC can be blended by ball milling and then nitrided in flowing nitrogen at elevated temperatures.

Halide production of TiCN uses an oxidizing vapor such as magnesium or sodium to reduce the TiCl4 in a reaction vessel at elevated temperatures of 500-1250 °C. The reduced Ti vapor condenses to form very fine metal powder, which rapidly reacts with any reactive species introduced into the reaction zone, such as nitrogen, ammonia, and methane ( Davidson et al., 1989 ). As of 1999, H. C. Starck (Goslar, Germany) was known to be using this method on a pilot plant scale to produce nanophase TiCN ( Lassner & Schubert, 1999 ).

Heterogeneous photocatalysis by organic materials: from fundamental to applications

3.1 Two-Dimensional g-C3N4 nanosheets

Reprinted with permission from J. Zhang, Y. Chen, X. Wang, Two-dimensional covalent carbon nitride nanosheets: synthesis, functionalization, and applications, Energy Environ. Sci. 8 (11) (2015) 3092–3108.

(A) Reprinted with permission from R. Boppella, et al., Black phosphorus supported Ni2P co-catalyst on graphitic carbon nitride enabling simultaneous boosting charge separation and surface reaction, Appl. Catal. B Environ. 242 (2019) 422–430. (B). Reprinted with permission from Z. Sun, et al., Construction of 2D/2D BiVO4/g-C3N4 nanosheet heterostructures with improved photocatalytic activity, J. Colloid Interface Sci. 533 (2019) 251–258. (C). Reprinted with permission from J. Wu, et al., An all-solid-state Z-scheme g-C3N4/Ag/Ag3VO4 photocatalyst with enhanced visible-light photocatalytic performance, Eur. J. Inorg. Chem. (2017) 2845–2853. (D). Reprinted with permission from J. Fu, et al., Ultrathin 2D/2D WO3/g-C3N4 step-scheme H2-production photocatalyst, Appl. Catal. B Environ. 243 (2019) 556–565.

Other Solid Acid and Basic Catalytic Materials

8.9.3.2 Nitrided carbon material as basic catalysts

3D mesoporous carbon nitride (C/N ratio c. 4.3), produced using mesoporous silica KIT-6 with 3D porous structure and different pore diameters as hard templates, and ethylenediamine and carbon tetrachloride as the sources for N and C, respectively, were recently prepared and tested as basic catalyst. These materials revealed excellent activity in the base-catalyzed Knoevenagel condensation of benzaldehyde and malononitrile, allowing high yield of the α,β-unsaturated nitrile in a short reaction time even at room temperature. These catalysts are highly stable and can be recyclable several times without affecting their activity. 264

Carbon Nitrides

Integration of carbon nitride nanosheets makes the hybrid aerogel stable for reusability by up to 5 adsorption-degradation cycles.

Related terms:

Download as PDF

About this page

2D Materials for electrochemical carbon dioxide reduction

8.2.4 2D carbon materials

Reproduced with permission from reference X.F. Sun, X.C. Kang, Q.G. Zhu, J. Ma, G.Y. Yang, Z.M. Liu, et al., Chem. Sci. 7 (2016) 2883-2887. Copyright 2016, The Royal Society of Chemistry.

Cyanide

Chemical Abstracts Service Registry Numbers : CAS 57-12-5 (CN); CAS 74-90-8 (Hydrogen cyanide); CAS 143-33-9 (Sodium cyanide); CAS 151-50-8 (Potassium cyanide)

Synonyms : Carbon nitride ion; Cyanide anion; Cyanide ion; Cyanure (French); Hydrocyanic acid; Isocyanide; Hydrocyanic acid sodium salt; Hydrocyanic acid potassium salt

Chemical/Pharmaceutical/Other Class : Cyanide is any one of a group of compounds containing the monovalent combining group CN. Inorganic cyanides are regarded as salts of hydrocyanic acid (hydrogen cyanide). Organic cyanides are usually called nitrites

Chemical Formulas : HCN (hydrogen cyanide); NaCN (sodium cyanide); KCN (potassium cyanide); CH3CN (acetonitrile)

Chemical Structure : −C

Eco-Design Rules for Plastics Sustainability

5.7 Design for Dimensional Stability

Too little (or too large) a polymer part can disturb a device made by assembling several parts of various materials. Sometimes, the dimension is fair, but a more or less strong warpage prevents correct assembly.

These phenomena are the consequences of:

the anisotropy of fiber-reinforced plastics

water uptake, particularly known for polyamides

the absorption of chemicals

the desorption and bleeding of humidity or additives such as plasticizers or other low MW organic additives

In addition, a wrong drawing can induce warpage of isotropic compounds. Anisotropic variations of the parameters listed above can also be responsible for warpage.

Moreover, plastics and rubbers are often simultaneously used with conventional materials, notably metals, whose coefficients of thermal expansion can be 10- to 100-times lower. This can promote high stresses and eventually failure of the device including these different materials.

Dimension variations can be immediate (thermal expansion), progressive (water uptake), or delayed after a given time of aging.

Fig. 5.7 displays the ins and outs concerning the dimensional stability of plastics.

5.7.1 Thermal Expansion or Retraction

The CTE can be volumetric or more frequently linear. It is defined as the fractional variation of volume (volumetric coefficient) or length (linear coefficient) per unit change in temperature. The volumetric coefficient is roughly three-times the linear one.

Of course, a temperature decay leads to a retraction.

Being thermal dependent, the validity range of test temperatures must be indicated.

Thermoplastics intrinsically have high coefficients of thermal expansion in the order of 10 −4 to 10 −5 /K.

To provide a general idea of thermoplastics coefficients of thermal linear expansion, Table 5.8 displays a statistical analysis for about 200 unfilled grades.

| Median | 10 −5 /K | 9 |

| Minimum | 10 −5 /K | 3 |

| Maximum | 10 −5 /K | 30 |

| Samples | 218 |

CTLE, coefficients of thermal linear expansion.

These values must be compared to those of other materials.

Steel and iron: 1–2×10 −5 /K.

Other common metals: 2–4×10 −5 /K.

Low CTE metals: 0.4–1×10 −5 /K.

Ceramics, oxides, carbides, nitrides, carbon, graphite: 0.2–1×10 −5 /K.

The CTE is significantly changed by:

The temperature, particularly if the glass transition temperature is reached.

The structure and morphology of the polymer.

The additives eventually used.

5.7.2 Shrinkage

Shrinkage after molding is a universal problem depending on:

The CTE; for given conditions, the shrinkage increases with the CTE.

The molding temperature; for given conditions, the shrinkage increases with the molding temperature.

The orientation of the macromolecules.

The orientation of fibers or acicular fillers.

The crystallinity; a possible crystallization after molding leads to a volume increase that minimizes the total shrinkage.

5.7.3 Warpage

Warpage or distortion can be due to:

local changes of formulation or processing parameters

Colorants, for example, can nucleate the polymer and locally favor shrinkage.

Fibers and acicular fillers can accumulate in certain spots of the mold, leading to local decreases of CTE, shrinkage, and increases of moduli, thus, leading to warpage.

Calcium carbonate fine powder and other spheroid fillers such as microballoons or glass beads decrease shrinkage and easily flow in the mold, thus, reducing warpage.

5.7.4 Water or Chemicals Uptake

All polymers absorb more or less humidity or water in quantities depending on:

The form of the water: humid air, liquid water, pure or polluted water

The recipe of the compound

The crystallinity of the polymer

The volume of absorbed water causes a dimensional increase. For example, for a given polyamide, the length increase is about 2.6% for a water content of 8% at equilibrium. Really, the absorption of water is extremely slow and, in the case of atmospheric changes, the equilibrium is not always reached, damping the effects of humidity variations.

Chemicals have the same effects, but the swelling can be much higher and absorption rate can be faster.

5.7.5 Aging, Desorption, Bleeding, Releasing of Organic Components

Residual monomers, oligomers, organic additives, particularly plasticizers, can degas, more so as the temperature and the airflow rise. Consequently, dimensions decrease. Components can also migrate toward other materials or bleed.

Released organic components pollute other materials and surroundings.

Production of clean energy by green ways

2.5.1 Hydrogen production by combo-technology

The enzyme hydrogenase (H2ase) with a [NiFeSe] cluster from Desulfomicrobium baculatum has been immobilized onto TiO2 nanoparticles. The enzyme produces H2 through a visible light-driven process with the help of dye-sensitized TiO2 nanoparticles for effective light harvesting under ambient conditions. Here, the nanoparticles are Ru dye sensitized with triethanolamine as a sacrificial electron donor. Immobilized H2ase can produce H2 at a turnover frequency of

H2 has been produced by photolysis of water in the presence of solar light in water by using immobilized H2ase with a [NiFeSe] cluster onto bioinspired synthetic nickel nanocatalyst (NiP) containing heptazine carbon nitride polymer, and melon (CNx) on its surface. It was found that immobilized H2ase has shown turnover numbers of > 50,000 mol H2 and

Nanosized Tubular Clay Minerals

9.1 Introduction

The surface structure of imogolite, as initially reported by Cradwick et al. (1972) from electron diffraction data, and corroborated by 27 Al and 29 Si nuclear magnetic resonance (NMR) studies ( Goodman et al., 1985; Ildefonse et al., 1994; Brown et al., 1999; Kang et al., 2010; Yucelen et al., 2011 ), can be described as an external curved gibbsite layer populated with orthosilicate anions on the inner surface. The presence of aluminol and silanol amphoteric groups gives imogolite interesting acid–base properties that, combined with its nanotubular and porous structure, make it attractive for a range of industrial applications from gas storage or catalysis to drug release or as adsorbent for pollutants from aqueous solutions. The small diameter of the inner pore (

1 nm) and its hydrophilic character ( Bonelli et al., 2013b ) make imogolite an interesting model material for the study of 1D confinement ( Belorizky et al., 2010 ), as opposed to other nanotubular materials such as carbon or boron nitride nanotubes, which are of a hydrophobic character.

Recent advances in imogolite and imogolite-like materials have been performed by research groups in the fields of physical chemistry of materials for adsorption and catalysis. The increasing interest in imogolite and imogolite-like materials is exemplified by the growing number of published papers in the field dealing with gas adsorption and surface modifications. In spite of recent advances, this review highlights aspects that clearly deserve more research, such as the origin of the structural charge, the control of point defects and the relative hydrophobicity of the external surface. Advances in these areas are important for the future development of functional materials based on imogolite and imogolite-like materials.

Nanomaterials for photocatalytic reduction of carbon dioxide

10.3.5 Carbon-based nanomaterials

Nanosized Tubular Clay Minerals

11.3 Ovalisation of the Imogolite

In the following discussion, the first experimental evidence of the ovalisation of imogolites was based on a detailed XRS analysis. The study was carried out on aluminogermanate nanotubes.

Fig. 11.7 shows XRS diagrams of dispersion of aluminogermanate nanotubes and of powder obtained by drying the same dispersion and then heating it at 250°C to evaporate the residual water inside and around these hydrophilic nanotubes. Oscillations are as broad for the powder as for the dispersion, which shows that nanotubes remain individual and do not assemble in bundles in the powder. The oscillations, however, appear strongly attenuated for the powder. Note also that the minima positions are unchanged. In principle, this effect could be attributed to a reduction in length of the nanotubes ( Fig. 11.2 A), but that can be ruled out since drying cannot induce nanotube cutting. In fact, it points towards a deformation in the shape of the nanotubes, as demonstrated in the following discussion.

Following the same steps as described here for cylindrical nanotubes, one easily shows that the X-ray intensity scattered by a powder of individual infinite nanotubes with an elliptic section basis is written as ( Amara, 2014 ):

In the hypothesis that the nanotube base section is elliptic along the entire length of the nanotube, one may now allow the elliptic deformation factor to vary from one tube to the other. A Gaussian distribution G(ν), centred around the value ν = 1 corresponding to the case of a undistorted nanotube, is introduced:

The variance Δ can be considered as an average degree of the deformation of the nanotubes.

Taking into account the distribution of the elliptic deformation, the scattered X-ray intensity by a powder of individual and uncorrelated nanotubes then becomes

As it is, the simple approach developed in this chapter shows that dried aluminogermanate imogolite nanotubes do ovalise. It has been predicted, based on molecular dynamics simulations, for aluminosilicate nanotubes and was not confirmed experimentally. Further simulations for aluminogermanate nanotubes and experimental studies on aluminosilicate nanotubes would be very interesting.

Physicochemical technologies for HRPs and risk control

8.5 Emerging technologies

In the earlier sections, we reviewed a variety of different traditional treatment techniques and their mechanisms of processing. Although these techniques can effectively remove HRPs from wastewater and have a considerable application, they also have many problems such as low efficiency, high cost, and easy to cause secondary pollution. Therefore, to improve the traditional technology or research and development of new processing technology has become the focus of this work. Recently, the scientific community has proposed various new processing technologies to solve the HRPs problem such as photocatalysis, electrosorption, and electroflocculation. These emerging technologies have extensively applied new theoretical systems and clean energy to efficiently and purposefully remove HRPs from wastewater. Therefore, they have advantages over traditional technologies in processing effectiveness and economic applicability. In this section, we mainly introduce the principles of each new processing technology and the current application and put forward the prospect for the future development of emerging technologies.

8.5.1 Photocatalysis technologies

Photocatalytic technology as a green renewable chemical technology has caused a wide range of scientific community. Due to its advantages of low price, excellent performance, energy saving, and environmental protection, it has an important application prospect in the field of environmental governance and renewable and clean energy. Photocatalysis is a new field, the essence of which is the photochemical reaction under the catalyst, thus combining photochemistry and catalytic chemistry. The photocatalytic material is a semiconductor material, and the reaction process mainly depends on the energy band structure of the semiconductor. The energy band structure of the semiconductor photocatalyst is composed of a valence band in which an electron is filled and a conduction band that is not filled with electrons. The bandwidth between the top of the valence band and the bottom of the conduction band is called as forbidden bandwidth. When the light with energy greater than or equal to the forbidden bandwidth irradiates the semiconductor photocatalyst, the electrons in the valence band will be excited to transition to the conduction band, and a hole will be created in the valence band, and an electron–hole pair will be generated in the semiconductor. At this time, the semiconductor material is in an unstable excited state, and to maintain its own stability, the semiconductor material in an excited state will release the absorbed external energy, that is, energy relaxation. The energy relaxation can occur in two main processes: (1) electrons and holes recombine inside the semiconductor, generate heat or release energy in the form of fluorescence; (2) electrons and holes are transferred from the inside of the semiconductor to the surface. The generated electrons have a strong reducing ability, and the holes have a strong oxidizing ability, and holes and electrons on the surface of the semiconductor material undergo a redox reaction with the acceptor substance on the surface of the catalyst. Fig. 8.4 shows the photocatalytic process of titanium dioxide (TiO2). The holes possess high positive oxidation potentials and therefore can oxidize nearly all chemicals, including oxidizing the water molecules to form hydroxyl radicals. At the same time, dissolved oxygen in the water can be reduced by the electrons on the conduction band to form superoxide radicals. Both hydroxyl radicals and superoxide radicals can degrade pollutants.

Currently, the commonly used semiconductor photocatalytic materials include single components, that is, titanium dioxide (TiO2), tungsten oxide, graphene oxide, graphite phase carbon nitride, zinc oxide, and composite components. Due to its high catalytic activity, low toxicity, good chemical stability, and good thermal stability, TiO2 is the most widely used and most efficient photocatalyst. Currently, a large number of studies have reported the removal of HRPs in wastewater by photocatalytic technology, especially HRPs. Table 8.9 shows recent studies on the removal of organic HRPs using photocatalytic techniques. Studies have shown that the amount of photocatalyst added has a great influence on the photocatalytic efficiency ( Rubio-Clemente et al., 2014 ). Before the optimum dosage, the more the catalyst is added, the higher the catalytic efficiency. Once excessively added, it will cause light to fail to reach part of the catalyst surface, and the catalyst will not absorb light energy. In addition, the catalyst also self-agglomerates, resulting in a decrease in the number of active sites. Other factors affecting photocatalytic efficiency include light intensity, the wavelength of light, solution pH, catalyst modification, and the presence of oxidant ( Yap et al., 2018 ).

| HRPs | Catalyst | Catalyst dose | Light source | Removal rate | References |

|---|---|---|---|---|---|

| 2,4-Dichlorophenol | Boron doped TiO2 | 1 g/L | UV | 89.7% | Bilgin Simsek (2017) |

| Ibuprofen | 96% | ||||

| Flurbiprofen | 98% | ||||

| Ibuprofen | Graphene quantum dot/AgVO3 | 0.2 g/L | Xenon lamp (420 nm) | 90% | Lei et al. (2016) |

| Ciprofloxacin | Ag/TiO2 | 0.5 g/L | UV | ∼100% | Durán-Álvarez et al. (2016) |

| Acetaminophen | TiO2 | 0.5 g/L | UV | 42% | Eskandarian et al. (2016) |

| Diclofenac | 92% | ||||

| Ibuprofen | 58% |

8.5.2 Electrosorption

Electrosorption technology is a new water treatment technology, which is based on the electrochemical double layer theory and uses the electrochemical characteristics of the charged electrode surface to realize the separation of ions in water. In the process of removing ionic state pollutants, by applying an external electric field to the electrode, the anions in the solution migrate to the anode and cations to the cathode, and a deionized zone is formed between the two-phase electrodes ( Fig. 8.5 ). In the process of electrode regeneration, ions adsorbed on the surface of the electrode can be separated from the electrode into the solution through short or reverse connection of the applied electric field to achieve the purpose of electrode regeneration. An electric double layer structure is formed when ions are adsorbed to the surface of the electrode. An outer tight layer in which the water dipole layer and the hydration cation are connected in series is formed on the surface of the cathode. On the surface of the anode, due to the low degree of anion hydration, the anion is directly adsorbed to the electrode surface by charge adsorption to form an inner tight layer. As with conventional adsorption techniques, the preparation of highly active electrode materials is at the heart of the further development of electrosorption technology. Generally, the electrode material should have the characteristics of large specific surface area, high electrical conductivity, good hydrophilicity, and reasonable pore size distribution. Currently used electrode materials are activated carbon, carbon nanotubes, and graphene.

Electrosorption technology has the advantages of simple equipment, simple experimental conditions, high efficiency, low energy consumption, low cost, easy maintenance, and no secondary pollution. Due to the high adsorption affinity of electrosorption for ionic contaminants, in recent years, the scientific community has paid extensive attention to the ability of electrosorption to remove heavy metals ( Table 8.10 ). As shown in the table, heavy metal ions in water can be effectively removed by using an electrode of different materials. Moreover, after the electrosorption is saturated, the regeneration process is simple, the energy consumption is low, and no reagent is needed, which is an ideal heavy metal treatment technology.

| Heavy metal | Electrode | Voltage | Adsorption capacity/Removal efficiency | Reference |

|---|---|---|---|---|

| Pb(Ⅱ) | Nitrogen-doped carbon | 1.2V | 481.5 mg/g | Ji et al. (2018) |

| Cr(Ⅵ) | Porous carbon | 1.0V | 91.58% | Zhang et al. (2018) |

| Ni(Ⅱ) | α-MnO2/Carbon Paper | 1.3V | 88.9% | Li et al. (2018) |

| Cd(Ⅱ) | Activated carbon cloth | 1.2V | 32% | Huang et al. (2016) |

| Pb(Ⅱ) | 43% | |||

| Cr(Ⅲ) | 52% | |||

| Pb(Ⅱ) | Single wall carbon nanotubes | 2.0V | 97.2%–99.6% | Liu et al. (2013) |

8.5.3 Electroflocculation

Currently, researchers have paid attention to the application of electrical flocculation technology in the removal of HRPs, and also applied to the actual wastewater treatment system. Maher et al. investigated the removal efficiency of estrogen in water by electrocoagulation technology using a bench-top iron electrocoagulation reactor ( Maher et al., 2019 ). Under optimum conditions, the removal efficiency of estrone, 17β-estradiol, estriol, and 17α-ethynylestradiol by electroflocculation technology reached 81%, 87%, 85%, and 97%, respectively. Akbal and Camcı used iron and aluminum electrodes to electroflocculate heavy metals such as copper, chromium, and nickel ( Akbal and Camcı, 2010 ). They found that the iron electrode was more efficient at removing these heavy metal ions. Under optimal conditions, the removal efficiencies for copper, chromium, and nickel were 99.9%, 99.9%, and 98%, respectively. Moreover, they also compared the methods of electroflocculation and chemical flocculation, suggesting the advantage of electrochemical treatment in costs and effectiveness.

CO2 adsorption by carbonaceous materials and nanomaterials

8.5 Novel carbonaceous structures for CO2 adsorption

8.5.1 Templated and doped carbonaceous structures for adsorption

8.5.2 Functionalized carbonaceous composite structures for CO2 capture

The composites were made by an in situ monomer association to form polymers connected with the mesoporous structured carbon using the precursor 2-methyl-2-oxadine polymerized via condensation with N-vinylformamide using a capillary condensation. The results showed high adsorption capacities of 3.1–3.5 mmol/g, surface area

8.5.3 The use of ionic liquid functionalization in nanoporous carbons

Defective polymeric carbon nitride: Fabrications, photocatalytic applications and perspectives

Abstract

Polymeric carbon nitride (CN) as a metal-free photocatalyst with suitable band gap has attracted increasing attention. However, pristine CN has a limited visible-light absorption range and also suffers a high recombination rate of photo-excited charge carriers, resulting in low photocatalytic activity. With the development of modern material characterization technology and electronic structure calculation technology, it is found that vacancy defects in CN play a more decisive role in determining the kinetics, energetics and mechanism of photocatalytic reactions. Therefore, much effort has been made in the past years to enhance the visible light activity of CN through defects control. This review provides the recent progresses and technologies on fabricating defective CN, in which the bottom-up and top-down preparation strategies are systematically summarized. In the meantime, the advancement of defective CN photocatalysts toward versatile applications such as water oxidation, hydrogen production, CO2 reduction, nitrogen fixation, H2O2 and organic synthesis, and pollutants removal are fully discussed. Finally, the existing opportunities and challenges of CN photocatalysts designed with vacancies defects are proposed to highlight the development direction of this field. This paper can lay a theoretical basis and guidance for the preparation of defective graphitic carbon nitride.

Carbon Nitride

Carbon nitride (CN) is one of the most promising materials to complement carbon in materials.

Related terms:

Download as PDF

About this page

Graphitic carbon nitride: Applications

Abstract

Semiconductor Photocatalysis for Water Purification

Carbon nitride-based photocatalysts

Cemented Carbides – An Outstanding Class of Refractory Based Alloys

WC–M(C,N)–Co System

Cubic carbonitrides of elements Nb, Ta, Ti, V, and Zr are often added to the cemented carbides in order to reach the desired properties ( Peng et al., 2014 ). Reciprocal miscibility gaps may occur in the cubic carbonitrides, which has been claimed to be of technical importance ( Peng et al., 2014 ). Therefore, knowledge of varying solubility of alloy elements in the binder and cubic phases is the basis of studying some properties of cemented carbides, such as grain size, hardness, and strength. For instance, investigating the changes of the WC solubility in the binder and cubic phases during the cooling stage is one possible way to study the grain growth of WC. According to the thermodynamic calculations based on the CALPHAD approach, it is convenient to investigate the effect of the factors on the stability of the cubic carbonitrides, such as alloy composition, sintering temperature, sintering partial pressure of N2 and so on. Peng et al. (2014) developed a self-consistent thermodynamic database for multicomponent cemented carbides. Using the thermodynamic database, the solubility of WC and the miscibility gap in the cubic carbonitride for the C–W–Ti–N system with unit carbon activity at 1427°C were calculated and presented in Fig. 4 ( Peng et al., 2014 ). Moreover, the miscibility gap in the fcc carbonitride for the C–Ta–Ti–N system with unit carbon activity at 1200°C (a possible pre-sintering temperature) and 1450°C (a possible sintering temperature) was also predicted in the reference ( Peng et al., 2014 ).

Reprinted from Peng, Y., Du, Y., Zhou, P., et al., 2014. CSUTDCC1-A thermodynamic database for multicomponent cemented carbides. Int. J. Refract. Met. Hard Mater. 42, 57–70, with permission from Elsevier.

Graphitic-Carbon Nitride for Hydrogen Storage

15.1 Introduction

Graphene–Carbon Nitride-Based Electrochemical Sensors for Biomolecules

2.1 Preparation of Carbon Nitride Nanomaterials

Generally, carbon nitride materials are prepared by the calcination method. The starting material containing carbon and nitrogen is heated around 600°C for

5 h. During this process, the bulk carbon nitride forms by self-condensation. The obtained bulk material is used in the next step of exfoliation. It involves dispersion in aqueous phase by ultrasound treatment. During the ultrasonication process, the bulk carbon nitride materials break down by exfoliation to form small nanosheets. The size and thickness of carbon nitride sheets decreases to form layered graphite-like CNNSs. The unexfoliated bulk particles are removed by centrifuging at low speed (

5000 rpm/10 min). The resulting supernatant liquid is dried in air to remove the water. Melamine has been used frequently as a starting material. Other starting materials include urea and dicyandiamide.

The general procedure to prepare carbon nitride nanomaterials is:

Heating of starting material in air/N2 → cooling → grinding to obtain fine powder of carbon nitride → ultrasound treatment in water → removal of unexfoliated bulkg-C3N4 by centrifuge → drying liquid supernatant in air → graphitic carbon nitride nanosheets (g−C3N4).

Carbon nitride photocatalysts

6.2.5 Carbon nitride-based heterojunctions

16.7% at a wavelength of 450 nm. Moreover, the presence of Ni(OH)2 exhibited an activity in H2 evolution that was seven times higher than that of the noble co-catalysts.

A comparative study on modified graphitic carbon nitride: Synthesis, characterization, and applications

5.1 Sensors and biosensors

Reprinted from J. Tian, Q. Liu, A.M. Asiri, A.O. Al-Youbi, X. Sun, Ultrathin graphitic carbon nitride nanosheet: a highly efficient fluorosensor for rapid, ultrasensitive detection of Cu(2 +). Anal. Chem. 85 (11) (2013) 5595–9 with permission from ACS.

In addition, CN materials are reported to be used as biosensors. The pathological process of various tissues and organs is accompanied by changes in pH, ion concentration, temperature, redox state, and other microenvironmental changes. Therefore, the development of CN signal tracing probes appeared to be a promising route for the development of advanced diagnostics. Mainly are reported 0D CN materials that use their semiconducting properties as optical markers to signal the signal changes of the biological microenvironment. These materials are reported to be used for sensing different analytes.

Reproduced from Y.-L.T. Ngo, W.M. Choi, J.S. Chung, S.H. Hur, Highly biocompatible phenylboronic acid-functionalized graphitic carbon nitride quantum dots for the selective glucose sensor. Sens. Actuators B, 282 (2019) 36–44 with permission (2019) of Elsevier.

Carbon-based materials for visible light photocatalysis

2.4 Graphitic carbon nitride (g-C3N4)

carbon nitride

Смотреть что такое «carbon nitride» в других словарях:

Beta carbon nitride — (β C3N4) is a material predicted to be harder than diamond. [ [http://www.nature.com/news/2000/000511/full/news000511 1.html Access : Crunchy filling : Nature News ] ] The material was first proposed in 1985 by Marvin Cohen and Amy Liu. Examining … Wikipedia

beta carbon nitride — noun a theoretical binary compound of carbon and nitrogen, CN, that is thought would have properties similar to diamond or boron nitride … Wiktionary

Carbon — (), but as most compounds with multiple single bonded oxygens on a single carbon it is unstable.] Cyanide (CN–), has a similar structure, but behaves much like a halide ion (pseudohalogen). For example it can form the nitride cyanogen molecule… … Wikipedia

nitride — /nuy truyd, trid/, n. Chem. a compound, containing two elements only, of which the more electronegative one is nitrogen. [1840 50; NITR + IDE] * * * ▪ chemical compound Introduction any of a class of chemical compounds in which nitrogen is… … Universalium

Nitride — In chemistry, a nitride is a compound of nitrogen where nitrogen has a formal oxidation state of −3. Nitrides are a large class of compounds with a wide range of properties and applications.[1] The nitride ion, N3–, is never encountered in… … Wikipedia

Carbon nanotube — Not to be confused with Carbon fiber. Part of a series of articles on Nanomaterials Fullerenes … Wikipedia

Boron nitride — IUPAC name Boron nitride Identifiers … Wikipedia

Titanium nitride — (titaniumnitrogen) (sometimes known as Tinite or TiNite) is an extremely hard ceramic material, often used as a coating on titanium alloy, steel, carbide, and aluminium components to improve the substrate s surface properties. Applied as a thin… … Wikipedia

Compounds of carbon — Scientists once thought that organic compounds are or could only be created by living organisms. Over time, human have learned how to synthesize organic compounds. There is an immense number of distinct compounds that contain carbon atoms. Some… … Wikipedia

Potential applications of carbon nanotubes — Carbon nanotubes have many potential applications, here is a list of some of the most important:tructural*clothes: waterproof tear resistant cloth fibers *combat jackets: MIT is working on combat jackets that use carbon nanotubes as ultrastrong… … Wikipedia

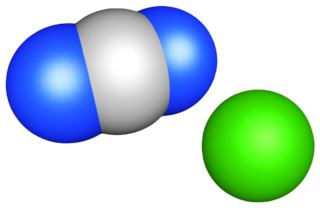

Carbon nitride

Carbon nitrides are compounds of carbon and nitrogen.

Contents

Covalent network compounds

Azafullerenes

Cyanofullerenes

Cyanogen

Dicyanopolyynes

Dicyanopolyynes are composed of a chain of carbon atoms with alternating single and triple bonds, terminated by nitrogen atoms. Although not a polyyne dicyanoacetylene otherwise fits within this series.

Percyanoheterocycles

Aromatic cyanocarbons

Other compounds

Anions

See also

Related Research Articles

A cyanide is a chemical compound that contains the group C≡N. This group, known as the cyano group, consists of a carbon atom triple-bonded to a nitrogen atom.

A fullerene is an allotrope of carbon whose molecule consists of carbon atoms connected by single and double bonds so as to form a closed or partially closed mesh, with fused rings of five to seven atoms. The molecule may be a hollow sphere, ellipsoid, tube, or many other shapes and sizes. Graphene, which is a flat mesh of regular hexagonal rings, can be seen as an extreme member of the family.

Carbon compounds are defined as chemical substances containing carbon. More compounds of carbon exist than any other chemical element except for hydrogen. Organic carbon compounds are far more numerous than inorganic carbon compounds. In general bonds of carbon with other elements are covalent bonds. Carbon is tetravalent but carbon free radicals and carbenes occur as short-lived intermediates. Ions of carbon are carbocations and carbanions are also short-lived. An important carbon property is catenation as the ability to form long carbon chains and rings.

Buckminsterfullerene is a type of fullerene with the formula C60. It has a cage-like fused-ring structure (truncated icosahedron) made of twenty hexagons and twelve pentagons, and resembles a soccer ball. Each carbon atom has three bonds. It is a black solid that dissolves in hydrocarbon solvents to produce a violet solution. The compound has received intense study, although few real world applications have been found.

Cyanogen is the chemical compound with the formula (CN)2. It is a colorless, toxic gas with a pungent odor. The molecule is a pseudohalogen. Cyanogen molecules consist of two CN groups – analogous to diatomic halogen molecules, such as Cl2, but far less oxidizing. The two cyano groups are bonded together at their carbon atoms: N≡C‒C≡N, although other isomers have been detected. The name is also used for the CN radical, and hence is used for compounds such as cyanogen bromide (NCBr) (but see also Cyano radical.)

A nitrile is any organic compound that has a −C≡N functional group. The prefix cyano- is used interchangeably with the term nitrile in industrial literature. Nitriles are found in many useful compounds, including methyl cyanoacrylate, used in super glue, and nitrile rubber, a nitrile-containing polymer used in latex-free laboratory and medical gloves. Nitrile rubber is also widely used as automotive and other seals since it is resistant to fuels and oils. Organic compounds containing multiple nitrile groups are known as cyanocarbons.

In chemistry, a nitride is a compound of nitrogen where nitrogen has a formal oxidation state of −3. Nitrides are a large class of compounds with a wide range of properties and applications.

Calcium cyanamide is the inorganic compound with the formula CaCN2. It is the calcium salt of the cyanamide ( CN 2−

2 ) anion. This chemical is used as fertilizer and is commercially known as nitrolime. It was first synthesized in 1898 by Adolph Frank and Nikodem Caro (Frank–Caro process).

Cyanamide is an organic compound with the formula CN2H2. This white solid is widely used in agriculture and the production of pharmaceuticals and other organic compounds. It is also used as an alcohol-deterrent drug. The molecule features a nitrile group attached to an amino group. Derivatives of this compound are also referred to as cyanamides, the most common being calcium cyanamide (CaCN2).

Cyanocarbons are a group of chemical compounds that contain several cyanide functional groups. Such substances generally are classified as organic compounds, since they are formally derived from hydrocarbons by replacing one or more hydrogen atoms with a cyanide group. The parent member is C(CN)4 (tetracyanomethane, also known as carbon tetracyanide). Organic chemists often refer to cyanides as nitriles.

Cyanogen bromide is the inorganic compound with the formula (CN)Br or BrCN. It is a colorless solid that is widely used to modify biopolymers, fragment proteins and peptides, and synthesize other compounds. The compound is classified as a pseudohalogen.

Dicyanoacetylene, also called carbon subnitride or but-2-ynedinitrile (IUPAC), is a compound of carbon and nitrogen with chemical formula C4N2. It has a linear molecular structure, N≡C−C≡C−C≡N (often abbreviated as NC4N), with alternating triple and single covalent bonds. It can be viewed as acetylene with the two hydrogen atoms replaced by cyanide groups.

2-Cyanoguanidine is a nitrile derived from guanidine. It is a dimer of cyanamide, from which it can be prepared. 2-Cyanoguanidine is a colourless solid that is soluble in water, acetone, and alcohol, but not nonpolar organic solvents.

Cyanometallates or cyanometalates are a class of coordination compounds, most often consisting only of cyanide ligands. Most are anions. Cyanide is a highly basic and small ligand, hence it readily saturates the coordination sphere of metal ions. The resulting cyanometallate anions are often used as ligands for building more complex structures called coordination polymers, the best known example of which is Prussian blue, a common dyestuff.

Graphitic carbon nitride (g-C3N4) is a family of carbon nitride compounds with a general formula near to C3N4 (albeit typically with non-zero amounts of hydrogen) and two major substructures based on heptazine and poly(triazine imide) units which, depending on reaction conditions, exhibit different degrees of condensation, properties and reactivities.

Cyanogen fluoride is an inorganic linear compound which consists of a fluorine in a single bond with carbon, and a nitrogen in a triple bond with carbon. It is a toxic and explosive gas at room temperature. It is used in organic synthesis and can be produced by pyrolysis of cyanuric fluoride or by fluorination of cyanogen.

Azidotetrazolate (CN7 − ) is an anion which forms a highly explosive series of salts. The ion is made by removing a proton from 5-azido-1H-tetrazole. The molecular structure contains a five-membered ring with four nitrogen atoms, and an azido side chain connected to the carbon atom. Several salts exist, but they are unstable and spontaneously explode. Rubidium azidotetrazolate was so unstable that it explodes while crystallizing. The potassium and caesium salt also spontaneously explode when dry.

Tetracyanomethane or carbon tetracyanide is a percyanoalkane molecular carbon nitride with formula C(CN)4. The structure can be considered as methane with all hydrogen atoms replaced by cyanide groups. It was first made by Erwin Mayer in 1969.