What do welders do

What do welders do

What does a Welder do?

A welder fabricates and puts together metal parts. They do this through the use of various machines that create intense heat. They also smooth and polish the metal surfaces once welded together. Welders must have the ability to study blueprints or project specifications in addition to calculating the dimensions of the parts to be welded. Welders also inspect materials or structures that need welding, monitor the process of welding as a caution for overheating, and maintain welding machinery and equipment they work with.

How to Become a Welder

Most welders have a high school diploma or equivalent and then earn a professional certification. Certifications can be gained at vocational schools, community colleges, or private programs. On-the-job training is often included in these training programs. Courses in these training programs teach you how to read blueprints, use shop mathematics, mechanical draw, basic physics, chemistry, and metallurgy classes.

A welder can also gain certification through the American Welding Society (AWS). According to AWS, this certification opens up opportunities for more money, leadership roles, and higher-level career challenges. AWS offers nine different certification categories from inspectors, supervisors, and educators to radiographic interpreters, welding engineers, and fabricators.

Job Description of a Welder

A welder’s primary duty is to join metal parts together. They may also fix holes in metal objects as well. They work on the metal components of various structures to include pipelines, bridges, power plants, buildings, refineries, automobiles, or ships. There is also more to welding than most people may realize. For instance, there are more than 100 different welding processes a welder can use, but the most common is arc welding.

Welders work full-time and often must work overtime. They can work up to 10 hours a day if needed. They primarily work outdoors and are exposed to hazardous situations on a daily basis. They may work in confined spaces, on scaffolding, or in inclement weather. Welders with the highest skill levels and a willingness to relocate have the greatest advantage for solid employment. Welders can also take their skills and compliment them with another trade, such as commercial diving.

Related Careers to Research:

Welder Career Video Transcript

Welders, cutters, solderers, and brazers use hand-held or remotely controlled equipment to join or cut metal parts, or to smooth surfaces. These workers study sketches and specifications to understand the full picture of the structure and materials before they start their work. Welders and cutters’ tools use high heat to soften the material.

Welders use these tools to join metal in a wide variety of industries, from car racing and manufacturing to steel beam construction. Cutters cut and trim metal objects, or dismantle large objects such as ships and railroad cars. Work may be outdoors on a scaffold or high platform, or indoors in confined areas. Bending, stooping, and heavy lifting are common. Soldering and brazing workers use molten metal to join two pieces of metal. Soldering involves precision tasks such as forming joins in electronic circuit boards, while brazing uses metals at higher temperatures to, for example, apply coatings to parts for protection against wear and corrosion. Other workers in this field manage machines or robots that perform welding, brazing, soldering, or heat treating tasks. These workers may also operate laser cutters or laser-beam machines.

Hazards include very hot materials and the intense light created by the arc. While employers are required to provide safely ventilated areas, these workers typically wear safety equipment to prevent injuries. Most positions are full-time; evenings, weekends, and overtime hours are common. High school education, along with technical and on-the-job training, is typically required to enter these fields. A certification or other skill credential is attractive to employers.

Article Citations

Bureau of Labor Statistics, U.S. Department of Labor, Occupational Outlook Handbook, Welders, Cutters, Solderers, and Brazers.

National Center for O*NET Development. 51-4121.06. O*NET OnLine.

The career video is in the public domain from the U. S. Department of Labor, Employment and Training Administration.

What Is a Welder and How to Become One

Table of Contents

What Do Welders Do?

The primary job of welders is to join metal together using intense heat. They work in a wide range of industries from manufacturing to aerospace to oil drilling. Other industries that use welders include automobile, manufacturing, construction, or maritime. As a welder, you execute projects according to your client’s specifications. You must understand the details of different welding metals, including stainless steel, aluminum, and brass, and you must be able to read blueprints and follow technical instructions. Additional job duties depend on your specific industry. You can also get voluntary certification from the American Welding Society (AWS) to prove your proficiency in the trade.

How to Become a Welder

To become a welder, you need to have manual dexterity, attention to detail, and physical strength and stamina. No formal post-secondary degrees are required to become a welder, but you should complete training to learn the trade. Some welders take welder training courses at a vocational school or through a welding firm. Others find apprenticeships with professional welders and learn on the job. Both types of training teach you how to read blueprints and mechanical drawings and the properties of a variety of metals. Most welders need to invest in their own equipment so that they can practice and become proficient in different types of welding. Qualified welders are in high demand in many different industries, from automotive to manufacturing. Becoming a certified welder is not required, but obtaining certification from national organizations such as the American Welding Society may make you more competitive in the job market.

Top 10 Skills Needed for Welders

Do your skills line up with what hiring managers are looking for when they are reviewing resumes for a Welder position? ZipRecruiter scanned over 9,000,000 job postings and created a list of the most commonly required abilities for Welders below.

Based on our assessment, mastering the skills below and listing them on your resume is critical in getting your Welder job application to the top of the stack.

What Do Welders Do at Work?

Welders work in a wide variety of locations and industries. Their daily activities depend on their company and the materials they are welding. Welders are required to follow blueprints or technical drawings to determine the specifications of the product. As a welder, you must know how to operate manual or semi-automatic welding equipment and power tools to fuse metal together. Employers expect you to understand the protocols of industry processes, such as TIG and MIG. Proficiency with the properties of materials is essential so that you are able to prevent the product from bending or breaking. Some welders also drive forklifts or pallet jacks to move products from one location to another. Welders are utilized in many different industries, including construction, manufacturing, aerospace, and the military.

Is a Welding Salary Worth the Hard Work?

Welding is a labor-intensive career; you operate large machinery and work with delicate materials using high heat. Precision is also essential in this career. But skilled workers in this trade can make a good salary with a fairly easy entry into the industry. Higher education is not required; most welders hold a high school diploma or equivalent, and many employers provide on-the-job training. Welding is also utilized in many different industries, such as construction, aerospace, and the military, so this career may provide opportunities to travel to a variety of interesting locations you would otherwise not have a chance to travel to and work on fascinating projects.

Welder Job Description Sample

With this Welder job description sample, you can get a good idea of what employers are looking for when hiring for this position. Remember, every employer is different and each will have unique qualifications when they hire for a Welder role.

We have an immediate opening for a highly-skilled Welder. In this position, you will work on in-house projects as well as travel to client locations to perform job duties on site. Your daily responsibilities will include reviewing specifications, laying out metal components, cutting, fabricating, and welding those pieces together to create tools and other metal parts. We expect our welders to complete each job within specific deadlines. Our ideal candidate has at least one year of welding experience and a working knowledge of standard welding tools and techniques.

Duties and Responsibilities

Requirements and Qualifications

Get New Jobs Emailed to You Daily

By clicking the button above, I agree to the ZipRecruiter Terms of Use and acknowledge I have read the Privacy Policy, and agree to receive email job alerts.

Could not find any Welder jobs within 25 miles of Volgograd, RU

* Salary estimates (ZipEstimate) are not verified by employers; actual compensation can vary considerably. To learn more about Compensation Estimates, please see our FAQ.

Get new jobs emailed to you daily

You Already Have an Account

We’re sending an email you can use to verify and access your account.

If you know your password, you can go to the sign in page.

What is welding? What do Welders do?

Содержимое разработки

Theme: What is welding? What do Welders do?

Educational: Students will be able to use new vocabulary and phrases talking about your profession

Developing: To develop speaking and listening skills in oral speech and reading the text. To practice working in groups. To try to choose right answer.

Bringing up: To respect national traditions and customs.

The type of the lesson: lesson-combination.

Inter subject connection: Russian, Kazakh.

The visual and teaching aids: a basic textbook, cards.

Organization moment: Greeting. Absence.

Presentation of the new theme:

Welding.

Read and translate the text.

Welding is a process when metal parts are joined together by the application of heat, pressure, or a combination of both. The processes of welding can be divided into two main groups:

•pressure welding, when the weld is achieved by pressure and

•heat welding, when the weld is achieved by heat. Heat welding is the most common welding process used today.

Nowadays welding is used instead of bolting and riveting in the construction of many types of structures, including bridges, buildings, and ships. It is also a basic process in the manufacture of machinery and in the motor and aircraft industries. It is necessary almost in all productions where metals are used.

The welding process depends greatly on the properties of the metals, the purpose of their application and the available equipment. Welding processes are classified according to the sources of heat and pressure used: gas welding, arc welding, and resistance welding. Other joining processes are laser welding, and electron-beam welding.

• сварку под давлением, когда сварной шов достигается давлением и

• тепловая сварка, когда сварной шов достигается теплом. Тепловая сварка является наиболее распространенным процессом сварки, используемым сегодня.

В настоящее время сварка используется вместо болтов и клепок при строительстве многих типов конструкций, включая мосты, здания и суда. Это также основной процесс в производстве машин, а также в автомобильной и авиационной промышленности. Это необходимо почти во всех производствах, где используются металлы.

pressure welding сварка давлением

heat welding сварка нагреванием

instead вместо, взамен

bolting скрепление болтами

to manufacture изготовлять

to depend зависеть от

gas welding газосварка

arc welding электродуговая сварка

resistance welding контактная сварка

laser welding лазерная сварка

electron-beam welding электронно-лучевая сварка

2. Answer the questions.

1. How can a process of welding be defined?

2. What are the two main groups of processes of welding?

3. How can we join metal parts together?

4. What is welding used for nowadays?

5. Where is welding necessary?

6. What do the welding processes of today include?

1. Сегодня сварка используется вместо соединения болтами.

2. Сварочный процесс в основном зависит от свойств металла.

3. Она необходима почти во всех производствах, где используется металл.

4. Сварка нагреванием – самый распространенный процесс сварки сегодня.

5. Это основной процесс в машиностроении.

4. Find 8 words and write them.

5. Read in the text.

1. …… are laser welding, and electron-beam welding.

2. …… in all productions where metals are used.

3. …… on the properties of the metals.

4. …… or a combination of both.

5. …… when the weld is achieved by heat.

Writing

Write five sentences (one per each paragraph) summarizing the main ideas of the text.

Reading

Skim the text to understand its main ideas

Our lesson is reaching the end. My dear, today you were very active and worked hard.

Your marks for today’ s lesson are…Thank you! See you later!

Text 2. What is welding and what do welders do?

Welding is the most economical and efficient way to join metals permanently. It is the only way of joining two or more pieces of metal to 10 make them act as a single piece. Welding is vital to our economy. It is often said that over 50% of the gross national product of the U.S.A. is related to welding in one way or another. Welding ranks high among industrial processes and involves more sciences and variables than those involved in any other industrial process. There are many ways to make a weld and many different kinds of welds. Some processes cause sparks and others do not even require extra heat. Welding can be done anywhere… outdoors or indoors, underwater and in outer space.

Nearly everything we use in our daily life is welded or made by equipment that is welded. Welders

help build metal products from coffeepots to skyscrapers. They help build space vehicles and millions

of other products ranging from oil drilling rigs to automobiles. In construction, welders are virtually rebuilding the world, extending subways, building bridges, and helping to improve the environment by building pollution control devices. The use of welding is practically unlimited. There is no lack of variety of the type of work that is done.

Welders are employed in many industry groups. Machinery manufacturers are responsible for agricultural, construction, and mining machinery. They are also involved in bulldozers, cranes, material handling equipment, food-processing machinery, papermaking and printing equipment, textiles, and office

machinery.

The fabricated metals products compiles another group including manufacturers of pressure vessels, heat exchangers, tanks, sheet metal, prefabricated metal buildings and architectural and ornamental work. Transportation is divided into two major groups: manufacturers of transportation equipment except motor vehicles; and motor vehicles and equipment. The first includes shipbuilding, aircraft, spacecraft, and railroads.

The second includes automobiles, trucks, buses, trailers, and associated equipment.

A small group of welders belongs to the group of repair services. This includes maintenance and repair on

automobiles or refers to the welding performed on industrial and electrical machinery to repair worn parts.

The mining, oil extraction, and gas extraction industries form yet another group. A large portion of the work

involves drilling and extracting oil and gas or mining of ores, stone, sand and gravel.

Welders are also employed in the primary metals industries to include steel mills, iron and steel foundries, smelting and refining plants. Much of 11 this work is maintenance and repair of facilities and equipment. Another group is the electrical and electronic equipment companies. Welding done by this group runs from work on electric generators, battery chargers, to household appliances.

Public administration employs welders to perform maintenance welding that is done on utilities, bridges,

government armories and bases, etc. Yet another group involves wholesale and retail establishments. These would include auto and agricultural equipment dealerships, metal service centers, and scrap yards.

Probably the smallest group of welders, but perhaps those with the biggest impact on the public are the artist and sculptors. The St. Louis Arch is possibly one of the best known. But there are many other fountains and sculptures in cities and neighborhoods around the world.

While-reading activity

Find the English equivalents for the following words and word combinations:

валовой национальный продукт, на открытом воздухе, в помещении, космический корабль, горное оборудование.

True or false?

1. Welding is an important process employed by modern industry.

2. All welding processes are similar.

3. All welding processes require work pieces to be heated.

4. The smallest group of welders belongs to the group of repair services.

5. Welding is the only way to join metals.

What do welders do?

Welders are professionals well-versed with the different welding processes. A welder uses numerous welding techniques to fabricate metal joints and components found in various industries and industrial products.

Welders are also responsible for ensuring that welding practices adhere to the prescribed quality and safety standards. They prepare materials and equipment for welding, inspecting, and analyzing the welded products to identify welding defects and their sources.

Table of Contents

What Is Welding? What Is the Role of a Welder?

Welding is the process of joining metals by applying heat, pressure, or a combination of both.

When two metal parts are to be connected, heat and pressure help melt the two metals. Once the molten metal solidifies, the two parts connect together with a permanent bond.

Can you think of a sector where you don’t require the joining of metals? Metal joints find their use in bridges, structures, housing, automobiles, trains, power plants, oil refineries, and many such areas. Wherever there’s metal to be joined, there’s welding to be had!

What Are the Different Types of Welding?

Depending upon the metals you want to join, the strength of joints desired, and ease of operation, you can use one of the several weldings.

If you are looking to become a welder, you can gain expertise in any of the following techniques. The most commonly used methods of welding are:

Arc Welding

Arc welding uses an electric arc from an external power supply source to generate heat to melt and join metals. The power supply connects to the electrode that carries current or melts directly into the weld pool due to the applied heat.

This welding method is simple, inexpensive, fast, and reliable. You can find the applications of arc welding in the automotive, shipbuilding, and construction industries.

Flux-Coated Arc Welding (FCAW)

FCAW is a variation of arc welding. The electrode used for FCAW contains a flux that protects the weld pool from contamination. FCAW has a high metal deposition rate, making it ideal for high-speed applications like mass production lines.

Mild steel, low-alloy steel, and stainless steel are common materials that you can join using FCAW.

Shielded-Metal Arc Welding(SMAW)

SMAW is very similar to flux-coated arc welding. The only difference between SMAW and FCAW is that SMAW electrodes are solid and have an external covering of flux, while FCAW electrodes have a tubular shape with an inner flux core.

Gas Metal Arc Welding(GMAW)

Gas-metal Arc Welding(GMAW) or metal inert gas welding(MIG) uses a consumable wire-type electrode. A shielding inert gas flows through the welding gun and helps protect the weld pool from atmospheric contamination.

Originally developed for aluminum and other non-ferrous metals, GMAW is now used for welding steel and its alloys.

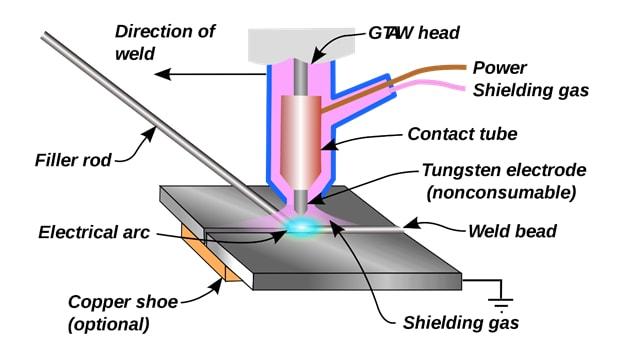

Gas Tungsten Arc Welding(GTAW)

GTAW or tungsten inert gas (TIG) welding is highly popular as it uses a non-consumable electrode. A tungsten electrode and a filler metal help create a joint between the two metals.

Inert gases such as argon or helium protect the area being welded from contamination, and most, although not all, welding applications will require filler metal.

START YOUR WELDING CAREER

Earn your degree in Welding Engineering Technology from NEIT and begin your new career path today!

Job Responsibilities of A Welder

Let’s take a look at the job responsibilities and the job description of a welder. Welders work in the manufacturing and construction industry and similar areas depending upon their skills and experience level.

A welder’s job description may involve one of the following responsibilities:

- Fabrication of metal joints and products Studying and analyzing drawings, blueprints, and sketches about metal joints. Calculating the dimension of weld required for securing the metal parts to be connected Ensuring that the workpiece adheres to prescribed quality and safety standards Performing on-site inspections to check for defects and deviations Recommending welding methods for joining a particular set of metals Executing post-welding operations such as filling of holes, deburring, and hammering out the bulges and bends Maintenance of the welding equipment and machinery

What are the Requirements for Becoming A Welder?

Given the scope, there is always a high demand for skilled people in the welding industry. If you want to take up a welding job or become a certified welding inspector, these are some of the requirements you must fulfill:

Education

If you wish to become a welder, you will need a GED or high school diploma. Once you’ve obtained your GED, you can apply for a welding certificate program.

A typical welding certification program can take six to eighteen months. During your certification program, you will learn the various welding methods and techniques. To further enhance your employability, you can pursue an apprenticeship program for additional and on-the-job-training.

An Associate Degree in Welding Engineering Technology can pave the path for a fulfilling career. Students will learn the theory and undergo welding training for joining materials using the various welding processes during this two-year welding program.

Your college might also engage you with construction projects or manufacturing jobs during your apprenticeship to enhance your skills as a welder.

Training

Along with the prerequisite education, training is an important part of becoming a welder. During their training and certification programs, welders work on live projects full time at the actual job location and handle welding equipment to complete their welding duties.

While working, the job instructor or shop floor manager will also teach welders about the various safety protocols important for handling power tools and equipment.

Certifications

To fulfill your job duties as a welder, you can also take up one of the certification programs. Some of the most popular types of welding certificates are as follows:

- Certified Welder (CW) Certified Welding Inspector (CWI) Senior Certified Welding Inspector (SCWI) Certified Welding Educator (CWE) Certified Welding Sales Representative (CWSR) Certified Associate Welding Inspector (CAWI) Certified Radiographic Interpreter (CRI) Certified Robotic Arc Welding (CRAW) Certified Welding Supervisor (CWS) Certified Welding Engineer (CWE)

Skills

As a welder, you must also possess these traits for welding mechanical structures, construction products, and surfaces and performing a variety of welding jobs:

- Physical fitness Great attention to detail Good dexterity and vision Good communication skills Ability to solve real-life problems Troubleshooting abilities Knowledge of welding specifications

What Industries Do Welders Work In?

Some of the top industries that offer attractive job offers to welders are:

- Mechanical, Architectural, and Structural Products Industry Mining, Agriculture & Construction Machinery Motor Vehicle, Heavy Automotive, Trailers, and Bodies fabrication General-Use Machinery

Other Employers of Welders

In addition to the above sectors, welders may also work as:

- Specialty Trade Contractors Self-Employed Welders Repair & Maintenance Specialists Wholesalers of Durable Goods Construction Welders

What Is the Workplace Environment Of a Welder Like?

There is a common misconception that welders work in hazardous conditions. However, the use of safety gear and equipment has helped create a safe workplace for industry workers.

A regular 40-hour working scheduling is common among welders. You can also improve your earnings by working overtime as there is a huge demand for welding.

Workers in the manufacturing and construction industry or repair work may join metal parts located at a great height and be at risk of accidents. Such factors make it essential for a welder to adhere to the guidelines taught during their job training or degree.

How Much Does a Welder Earn?

How to Become a Welder?

The process of becoming a welder can be roughly divided into four steps. They are:

- Earn a High School Diploma or GED: A high-school diploma helps provide the basic foundation necessary for taking up any job. As welders require technical expertise, the arithmetic, and geometry that you learn initially help a lot. Get a Certification or a Degree in Welding: You can obtain your certification or associate’s degree from the USA’s best colleges for welding to improve your prospects of a fulfilling career. Certification programs usually last from six to eighteen months, while an associate degree generally takes two years. Participate in Training or Apprenticeship: As a welder taking up apprenticeships in a manufacturing, structural, or repair company can help learn the trade practically. With the hands-on welding experience in joining various metal surfaces and metal parts, your skills improve, and your career can get off to a good start. Earn a Welding Certification: Getting certified is a great way to validate your knowledge of welding and also highlight your level of expertise to potential employers. The American Welding Society (AWS) issues most of these certificates.

Ready to kickstart your welding career? Visit our website to learn more about our full-time courses and degree programs in welding technology.

What does a welder do?

Would you make a good welder? Take our career test and find your match with over 800 careers.

What is a Welder?

A welder is a skilled tradesperson who joins metal together, or fills and repairs holes on metal constructions through the use of intense heat and gas.

Welders work on all types of industrial, manufacturing, and construction applications; some even work underwater to repair oil rig foundations, ship hulls and other types of subaquatic structures. Due to the almost universal need for their skills, welders are in high demand worldwide.

In this article:

What does a Welder do?

The specific job duties of a welder vary depending on the skill of the welder and the industry in which they work.

While those who use robots are usually confined to working in a factory, those who weld by hand can work in almost any type of application. Construction welders join steel I-beams for high-rise structures, skyscrapers, and any other type of building that uses metal. Welders can also work on a car racing team, repairing the chassis of a damaged car or building an entirely new one. NASA even employs highly skilled welders to work on aerospace applications.

Depending on the project, welders use one of the more than 100 welding methods. In arc welding, workers either weld by hand or machine. It is the most common method of welding in which an arc of electric current combines two metal pieces with a special welding rod. Oxy-fuel welding, oxyacetylene welding, or gas welding use gasses and oxygen to produce the heat needed to melt and join pieces of metal. Other types include resistance welding, shielded metal arc welding, submerged arc welding, and the more modern laser beam welding processes. Welders may specialize in one or more of these types, as certain metals will require specific welding methods.

Welders typically work from blueprints or specifications, then use their knowledge of base metals and joining techniques to select the appropriate material for the job. They cut, position, and spot weld the metal in preparation for one of the many welding processes. The difficulty of the job depends on the type of metal and position. Hard metals like titanium and steel tend to warp less and are therefore easier to join together. Malleable, soft materials like aluminum are easily warped and subject to damage if the surface is not thoroughly cleaned; special care must be taken on the part of the welder to prevent imperfections in the weld.

Regardless of the type, welders are exposed to intense and blinding heat and must take special care to ensure their own safety and the safety of those around them. Welders wear special gloves and aprons to prevent sparks and flames from burning their clothes and skin. They also wear a special mask to prevent flash burns, which are much like an ocular sunburn. In addition to taking safety precautions, welders must monitor the metal they are welding closely. Special care is taken to prevent overheating of the metal which leads to warping, distortion, shrinkage or expansion. Welders also maintain their equipment and work with various power tools, including a grinder, to prepare metal surfaces for welding.

Are you suited to be a welder?

Welders have distinct personalities. They tend to be realistic individuals, which means they’re independent, stable, persistent, genuine, practical, and thrifty. They like tasks that are tactile, physical, athletic, or mechanical. Some of them are also conventional, meaning they’re conscientious and conservative.

Does this sound like you? Take our free career test to find out if welder is one of your top career matches.

What is the workplace of a Welder like?

Many welders work a regular 40-hour work week though opportunities for overtime work are frequent due to the demand for welding. It is estimated that one in five welders work 50 hours or more per seven-day period. They are exposed to a number of welding-related hazards while on the job including the inhalation of gasses and particulates and the danger of falling for construction welders working on high platforms. Some companies employ welders on overnight shifts so that production can continue 24 hours a day, year-round.

Frequently Asked Questions

How long does it take to become a Welder?

There is more than one way to become a welder. The selected educational track determines the length of time you will dedicate to the process:

Welding Apprenticeship / on-the-job training – varies greatly, depending on employer and position

Welding Certificate – six to eighteen months

Welding Associate Degree – two years

Welding Bachelor’s Degree – four years

Should I become a Welder?

Before pursuing this occupation, aspiring welders should consider both its demands and the opportunities it presents.

Commercial welders must be physically and mentally fit, with excellent hand-eye coordination, and the ability to remain focused on a repetitive task for long periods of time.

Welders are exposed to hot metal, bright lights, and noxious fumes every day. Many jobs involve working around heavy equipment that can cause serious injury.

Welders need to be prepared to work in tight spaces, at elevated heights, and outside in all seasons. They need to endure many hours standing or crouching and be willing to wear goggles and other safety gear.

The occupation calls for several skills:

• Ability to understand technical plans, drawings, and blueprints

• Capacity to picture what you have to do before you do it

• Attention to detail – to spot flaws and defects, worn parts, and other workplace issues

• Problem-solving skills

• Math skills / Ability to calculate dimensions and take accurate measurements

Welders find work in a myriad of industries:

• Construction

• Civil engineering

• Construction engineering

• Aerospace

• Automotive

• Agricultural engineering

• Power

• Shipbuilding and repair

• Renewable energy

• Oil and gas

• Overseas construction projects

If you are comfortable with the working conditions common in the field; if the traits and skills needed in the job are aligned with your own; if the industries which hire welders appeal to you, this may be a career fit for you.

What are Welders like?

Based on our pool of users, welders tend to be predominately realistic and investigative people. These two traits clearly reflect the pragmatic tasks of a welder: to use a precise application of heat to melt, mingle, and join two pieces of metal; to monitor the welding process to prevent overheating; and to examine the welds for flaws.

Steps to becoming a Welder

Welding is sometimes described more as an art than a craft. To become a welder is to commit to a profession with many faces and levels, one that requires considerable training and often multiple certifications.

Welders are also known as:

Aluminum Welder Fabrication Welder Maintenance Welder Sub Arc Operator Welder Operator