What is just in time production

What is just in time production

What Are the Main Benefits of a JIT (Just in Time) Production Strategy?

Just-in-time production (JIT) is a business strategy in which a manufacturer produces each item as it is ordered, rather than keeping an extensive amount of surplus products on hand. The chief benefit of the strategy is that it allows businesses to ensure that there is always a buyer for any item produced, keeping inventories low. If there are no customers wanting to purchase an item, production stops.

Key Takeaways

Why Low Inventories Matter

The JIT production process means inventory levels are kept to a minimum. A low inventory figure on the balance sheet means a higher inventory turnover ratio, making the company look more efficient. The inventory turnover ratio is a metric used in corporate finance to estimate how efficiently a company is selling its products.

By dividing the total cost of goods sold (COGS) by the average inventory over a given period, the inventory turnover ratio reflects the number of times the company has sold its total average inventory. A company with little to no inventory has a much higher ratio than a company with equivalent COGS expenses that utilizes a more anticipatory production strategy.

High inventory turnover ratios are considered a good sign of operational efficiency, effective purchasing management, and productive use of advertising and promotional campaigns aimed at generating sales.

How the JIT Strategy Boosts Profitability

The JIT production strategy has an important effect on other measures of corporate efficiency and profitability. Lower inventory means a reduced total asset figure on the balance sheet, all else being equal. This translates directly into a higher return on total assets (ROTA) ratio. The ROTA ratio divides a company’s earnings before interest and taxes by its total assets to determine how effectively the business’s operational model utilizes invested funds to generate profit.

The asset turnover ratio is another efficiency ratio that reflects a company’s ability to generate revenue by dividing net sales by average assets for a specific time period. Decreased inventory means a smaller denominator in both these formulas, leading to healthier ratios across the board.

JIT Means Lower Costs For Materials and Labor

Apart from the improvement in comparative metrics, the JIT production strategy is advantageous to a company’s profitability in many other ways. Sales-contingent production means lower costs for both raw materials and labor. If a business is not looking to produce a backlog of goods for sale, it need only purchase those materials required for items that have already been ordered, leading to a reduction in COGS.

Labor expenses are also reduced since the number of man-hours needed to fulfill orders is likely lower than would be required for full-time production. On-demand production means fewer items sitting on shelves depreciating in value if sales take a downturn, and the risk of losing money if a product becomes obsolete is virtually eliminated. While many companies must invest capital in large warehouses to store products for sale, minimal inventory means almost nonexistent storage expenses. The reduction of these key production and operational expenses means higher gross and operational profits, which directly contribute to a healthier bottom line.

Just-in-Time (JIT)

What Is Just-in-Time (JIT)?

The just-in-time (JIT) inventory system is a management strategy that aligns raw-material orders from suppliers directly with production schedules. Companies employ this inventory strategy to increase efficiency and decrease waste by receiving goods only as they need them for the production process, which reduces inventory costs. This method requires producers to forecast demand accurately.

Key Takeaways

Just In Time

How Does Just-in-Time Inventory Work?

The just-in-time (JIT) inventory system minimizes inventory and increases efficiency. JIT production systems cut inventory costs because manufacturers receive materials and parts as needed for production and do not have to pay storage costs. Manufacturers are also not left with unwanted inventory if an order is canceled or not fulfilled.

One example of a JIT inventory system is a car manufacturer that operates with low inventory levels but heavily relies on its supply chain to deliver the parts it requires to build cars on an as-needed basis. Consequently, the manufacturer orders the parts required to assemble the vehicles only after an order is received.

For JIT manufacturing to succeed, companies must have steady production, high-quality workmanship, glitch-free plant machinery, and reliable suppliers.

The JIT inventory system contrasts with just-in-case strategies, where producers hold sufficient inventories to have enough products to absorb maximum market demand.

Advantages and Disadvantages of JIT

JIT inventory systems have several advantages over traditional models. Production runs are short, which means that manufacturers can quickly move from one product to another. Also, this method reduces costs by minimizing warehouse needs. Companies also spend less money on raw materials because they buy just enough resources to make the ordered products and no more.

The disadvantages of JIT inventory systems involve potential disruptions in the supply chain. If a raw-materials supplier has a breakdown and cannot deliver the goods promptly, this could conceivably stall the entire production line. A sudden unexpected order for goods may delay the delivery of finished products to end clients.

Example of JIT

Famous for its JIT inventory system, Toyota Motor Corporation orders parts only when it receives new car orders. Although the company installed this method in the 1970s, it took 20 years to perfect it.

Sadly, Toyota’s JIT inventory system nearly caused the company to come to a halt in February 1997, after a fire at Japanese-owned automotive parts supplier Aisin decimated its capacity to produce P-valves for Toyota’s vehicles. Because Aisin is the sole supplier of this part, its weeks-long shutdown caused Toyota to halt production for several days.

This caused a ripple effect, where other Toyota parts suppliers likewise had to temporarily shut down because the automaker had no need for their parts during that time period. Consequently, this fire cost Toyota 160 billion yen in revenue.

At the start of the COVID-19 pandemic and its ripple effect on the economy and supply chain, things like paper surgical masks, toilet paper, and hand sanitizer experienced disruption. This was because inputs from overseas factories and warehouses could not be delivered in time to meet the surge in demand caused by the pandemic.

Special Considerations

Kanban is a Japanese scheduling system that’s often used in conjunction with lean manufacturing and JIT. Taiichi Ohno, an industrial engineer at Toyota, developed kanban in an effort to improve manufacturing efficiency.

The Kanban system highlights problem areas by measuring lead and cycle times across the production process, which helps identify upper limits for work-in-process inventory to avoid overcapacity.

What Exactly Do You Mean by Just-in-Time?

A just-in-time (JIT) inventory system is a management strategy that has a company receive goods as close as possible to when they are actually needed. So, if a car assembly plant needs to install airbags, it does not keep a stock of airbags on its shelves but receives them as those cars come onto the assembly line.

Is Just-in-Time Manufacturing Risky?

A chief benefit of a JIT system is that it minimizes the need for a company to store large quantities of inventory, which improves efficiency and provides substantial cost savings. However, if there is a supply or demand shock, it can bring everything to a halt.

For instance, at the beginning of the 2020’s economic crisis, everything from ventilators to surgical masks experienced disruption as inputs from overseas could not reach their destinations in time to meet a surge in demand.

What Types of Companies Use JIT?

The JIT inventory system is popular with small businesses and major corporations alike because it enhances cash flow and reduces the capital needed to run the business. Retailers, restaurants, on-demand publishing, tech manufacturing, and automobile manufacturing are examples of industries that have benefited from just-in-time inventory.

Who Invented JIT Inventory Management?

JIT is attributed to the Japanese automaker Toyota Motor Corporation. Executives at Toyota in the 1970s reasoned that the company could adapt more quickly and efficiently to changes in trends or demands for model changes if it did not keep any more inventory in-store than was immediately needed.

What Is “Just in Time”?

Just in Time (or JIT) is a powerful method to reduce costs and increase efficiency. However, it is also very difficult to achieve. Most times when a Western company tells me it does JIT, it turns out that this is merely wishful thinking. Let me tell you what JIT really is. I will also talk a bit about the history of JIT. Finally, I will show you a few negative examples of wishful thinking common in modern industry. In my next posts I will go into more details on how to make it work.

Historical Background

The idea of Just in Time originated with Kiichiro Toyoda (1894–1952), founder of the Toyota Motor Company. During a trip to England, Toyoda missed a train. The train was on time, but Toyoda was slightly late. This had him thinking about analogies for material. Material arriving too late is obviously bad, as it causes stops and delays. However, material arriving too early is also bad, as it increases material. Hence, the material had to arrive just on time. Combined with a grammatical error, this is now the famous Just in Time (JIT), first mentioned at Toyota around 1936.

However, having the idea is one thing; creating a successful implementation is another. This can be credited to the Toyota employee and mastermind behind the Toyota Production System, Taiichi Ohno.

The experience of Ohno and Toyota during World War II probably helped too. The company was constantly plagued by material shortages, and having unused material sitting around while they lacked other materials was especially painful. In combination with pull, kanban, and many other things, Ohno successfully managed to reduce inventories. This also included the use of Just in Time.

The Western world became curious about the success of Toyota only after the 1973 oil crisis, which hurt many Western car makers but not Toyota. A large study and the resulting bestseller The Machine That Changed the World showed that Japanese car makers were indeed far superior in cost and quality. This started the whole Lean Production wave.

The topic of JIT in particular started to take off around 1980 but reached its peak in 1990. Since then it has been still present but is less frequently mentioned in publications. The Google Ngram graph below shows the occurrence of JIT in English Literature over time, and the 1990 peak is clearly visible.

What Is Just in Time?

In its pure theory, Just in Time is a method where material arrives just on (in) time when it is needed. This is valid both for purchased or delivered material and material processed on site. Ideally, the moment a worker needs a part, it should arrive right where he needs it.

This is of particular interest for value-adding process in the material flow. Of course, non-value-adding processes also benefit from JIT, although the benefit for the actual manufacturing processes are a bit bigger. In any case, you should work on reducing and eliminating non-value adding processes (a.k.a. waste).

However, the material arriving Just in Time is only half of the story. The other half is often missed. The material also has to depart on time. Hence, in a perfect JIT world, all material would be either in transport or currently worked on. There would be no idle inventory anywhere.

But, back to reality. We do not have a perfect world. Even for good companies, there are small inventories needed to buffer fluctuations. Working without any buffer inventories will cause delays in the machines, even for good companies. The important part is that inventories between processes should be reduced, and JIT does not only require an arrival on time but also little waiting times for material between processes.

How Little Material Do I Need for Just in Time?

JIT is reduction of material in the supply chain, with particular focus of the material arriving just when it is needed. Yet, it is almost impossible to truly hand over the material just at the moment when the worker needs it. Even good companies have small inventories at the manufacturing location, and other small inventory buffers at different points along the supply chain. So, how little do you need to call your process JIT?

Unfortunately, there is no clear answer. Nobody has defined when you are JIT. In my view, if you have more than a day’s worth of material at the plant, then you are probably not JIT. But, if another company wants to call its month’s worth of inventory “Just in Time,” there is nobody who can stop them from doing so (although I would strongly disagree!).

Why Just in Time Is Useful

Just in Time primarily reduces inventory. This reduction in inventory then reduces cost. Factors relevant here are, for example, less tied-up capital, less handling, less storage cost, less administrative overhead for inventory, and less scrapping or obsolescence (see The Hidden and Not-So-Hidden Costs of Inventory). However, there are two derived benefits from reduced inventory trough JIT that I would like to especially point out.

Faster Reaction

Product design changes will progress through the system faster, defects will be detected earlier downstream, production plan adjustments can be reacted on faster, and so on. Overall, this is one of the big benefits of JIT. Yet, this is the more difficult part where your material has to both depart and arrive on time.

More Space in Manufacturing

The combined cost of storing material is not equal everywhere. The closer you get to the manufacturing processes, the more precious your floor space becomes. The less material you have at manufacturing, the closer together you can place your processes. This is good for efficiency. If you have large piles of material around your processes, then the processes have to be farther apart. Workers have to walk more, material has to be transported farther, information flow is slowed down, and so on.

With JIT, you can reduce the inventory, especially around the processes where space is most valuable. Best of all, for this it is enough when the part arrives just on (in) time. It does not matter when the part departed. You do not need to reduce inventory along the entire supply chain, but only at the last stop where the material is consumed. The benefit of reducing inventory around your machines and processes can also be achieved simply by storing the material elsewhere, without an overall reduction in material. Of course, reducing inventory still has lots of other benefits and is usually worthwhile.

How Not to Do It

Some companies outright call their inventory JIT and are done with it. At a public tour of a large automotive manufacturer, we went through large halls stuffed to the roof with materials, while the guide casually remarked, “This is our JIT inventory.”

Another company used a third-party warehouse across the street. Most of the material was stored in this warehouse. Since, officially, it was not yet their material, it wasn’t even counted as inventory, even though the whole expense was forwarded to the company through the purchasing price. Their ability to get material from across the street was then called JIT, even though this usually required a three-day notice beforehand.

Overall, JIT is quite powerful, bringing all the benefits of reduced inventory, especially at the critical manufacturing processes where space is at a premium. Unfortunately, while it is easy to claim to be JIT, it is much more difficult to actually get it working. In my next posts I will go into more detail on the different ways to move toward JIT. In the meantime, go out and organize your industry!

11 thoughts on “What Is “Just in Time”?”

Christoph, I agree. JIT is a great process if everyone owns up to it. You need to rely on responsible vendors. If a vendor is late so are you. That is why you need to have lead times. I was very fortune in a company I worked in where we hired consultants to review our process. This is what we learned: 1. Vendors are internal as well as external

2. Review your process with teammates of all departments. People are department focused instead of plant focused. You will fine that you may be affecting other departments to be slow when you make decisions for you own department. 3. Departments should work close with their previous departments. For example, packaging department should be on top of production to reduce reworks and defects. Production problems caught as it is being produced will save you quality issues as well as time.

4. Every one should be audited to make sure they are taking care of their internal and external.

5. Monthly meeting should focused on process flow as well as regular plant activities. Including safety. This can also slow your process.

I can go on and on. In the JIT process that we participated we reduced lead time 21 days down to 7 days by reorganizing, cutting down on waste, and communicating throughout the entire plant. Teams works in JIT.

JIT needs to be sustained by auditing processes, doing Gemba walks and having Kaizen events to continually improve the process.

Hi Ismelda, thanks for the long comment. Sounds like your project was quite a success 🙂 In my next two posts I will describe some methods on how to improve your lead time/ JIT.

I know JIT works it takes dedication from the top down. It reduces inventory and production time. It does take time to educate and train how everyone thinks. With low inventory you find vendor problens quicker than the normal manufactung systems. When you are truly JIT in Priduction you will find manufactung challenges at a faster pace this will allow you to detect the problem this will cut cost because you are not producing products that don’t met quality standards.

This may be an oversimplification but, If a “system” exists where demand is viewed holistically vs in a linear way…. then the entire supply chain (External Supply Vendors / “all employees” / Strategic Customers) is involved “ALL THE TIME”. Lead times become reduced. Forecasting get partially reduced by real demand…

I really enjoyed this article

Lean Manufacturing Tools

Lean Manufacturing Tools, Techniques and Philosophy | Lean and Related Business Improvement Ideas

Just in Time (JIT) Production

What is Just in Time?

Just in Time (JIT), as the name suggests, is a management philosophy that calls for the production of what the customer wants, when they want it, in the quantities requested, where they want it, without it being delayed in inventory.

So instead of building large stocks of what you think the customer might want you only make exactly what the customer actually asks for when they ask for it. This allows you to concentrate your resources on only fulfilling what you are going to be paid for rather than building for stock.

Within a Just in Time manufacturing system, each process will only produce what the next process in sequence is calling for.

The Origins and History of JIT

JIT is generally accepted as being a concept invented by Taiichi Ohno of Toyota; after World War2 resources were very scarce in Japan so using them to create something that the customer did not actually want right now was not a good idea.

On a visit to the US the management team of Toyota were inspired by, of all things, how they saw a supermarket (Piggly Wiggly) handle their inventory. Only what was removed from the shelves by the customers was actually replenished and ordered from suppliers. In this way shelves never became empty, nor did they end up overflowing with excessive inventory.

Taiichi Ohno was tasked by Eiji Toyoda to make production more efficient through implementing these ideas and pull production with just in time concepts was developed. It took more than 15 years for Toyota to perfect their ideas and it was not introduced into western manufacturing until the end of the 1970’s.

With a JIT system each process pulls from the preceding process’ “supermarket” and that process will then work to replenish those shelves.

How does JIT differ from traditional manufacturing?

In traditional manufacturing we try to predict what the customer will want and we will create a forecast (or guess) against which we will produce our products. We will also try to produce those products in large batches as the belief is that will make machines and processes more efficient, especially if those machines require a long time to setup. This will typically result in long lead times through our processes, huge amounts of Work In Process (WIP) stocks and also large quantities of finished goods stocks that have not yet been ordered by our customers. This is what many now call “Just in Case” manufacturing.

If the customer does order something that is not in our current stocks they will either have to wait many weeks or even months for the product to be manufactured or work will be hurried through the system by progress chasers causing a huge amount of disruption to the production schedule.

These systems are often run by Manufacturing Resource Planning (MRP2) programs that will try to schedule each and every process within the facility. These software packages will seek to control every step and everything requires careful and often complex planning.

A Just in Time system on the other hand will seek to use simple visual tools known as Kanbans to pull production through the processes according to what the customer actually takes. It massively reduces the amount of stock held and will reduce lead times by a significant amount, often from weeks to just a few hours or days.

The benefits of a JIT system

The following are some of the many benefits that you could gain through the implementation of just in time:

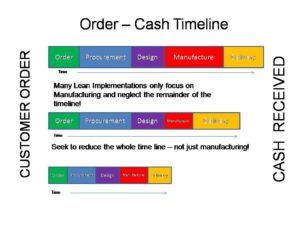

The Order to Cash Timeline; as you reduce your lead time the quicker you get your cash.

Inventory Hides Problems

Many definitions of Just in Time and Lean itself will state that waste reduction is the aim; waste reduction, however, is actually something that you achieve through trying to implement the flow and other improvements required to achieve just in time and not an end in itself.

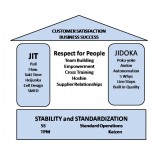

Requirements for implementing Just in Time

Just in Time is just one of the pillars of a lean manufacturing system and as such it cannot be implemented in isolation and without a firm foundation on which to build. Trying to reduce batch sizes without tackling setup times for instance cannot be done. The following are some of the things that must be implemented for JIT to be able to work:

AccountingTools

Accounting CPE Courses & Books

AccountingTools

Related Courses

What is Just-in-Time Production?

Just-in-time production minimizes the time, labor, and materials in a manufacturing process. It does so by only producing goods as they are needed. The desired outcome is a streamlined production system that maintains a minimal amount of on-site raw materials, minimal wait times in the production process, and small batch sizes. Several characteristics of a just-in-time production process are:

Daily or hourly deliveries of small quantities of parts from suppliers

Certification of supplier quality, so that no receiving inspections are needed

The use of kanbans to drive the demand at each workstation

The arrangement of the production area into flexible work centers

The compression of the production area so that in-process goods can be directly handed off to the next work center in a production flow

On-site inspection of each in-process product from the preceding work center, so that flaws are discovered at once

The use of rapid machine setups, so that production runs can be as short as one unit

The cross-training of employees, so that they are certified to work on multiple tasks

Production stops as soon as the immediate demand level has been fulfilled

Immediate shipment of completed goods to customers as soon as an order has been fulfilled

Advantages of Just-in-Time Production

There are several benefits of a just-in-time production system. One is a drastic decline in the amount of working capital needed, since inventory levels are quite low. Another benefit is a reduction in the amount of waste, since inspections are conducted at every workstation, not allowing defective goods to pile up anywhere in the process. Further, there is no finished goods obsolescence, since goods are only produced if they can be immediately sold. In addition, the square footage needed by the production area is reduced, since the work area is compressed. There is also a reduced need for materials handling equipment, since the work centers are positioned so close together that parts can be manually handed off from one workstation to the next.

Disadvantages of Just-in-Time Production

The main flaw with a just-in-time system is that an interruption to the system can quickly shut down the process, since there is no buffer built into the system. For example, when a machine breaks down for which there is no backup machine and no arrangement to outsource work, the downstream operations fed by that machine are immediately starved of inputs, and must stop.

:max_bytes(150000):strip_icc()/Group1805-3b9f749674f0434184ef75020339bd35.jpg)

:max_bytes(150000):strip_icc()/TimothyLi-picture1-4fb5c746f503451bacfee414a08f5c1f.jpg)

:max_bytes(150000):strip_icc()/image0-MichaelBoyle-d90f2cc61d274246a2be03cdd144f699.jpeg)

:max_bytes(150000):strip_icc()/IMG_5330-abb96c81199643e9b6ec5835b3daeb02.jpeg)